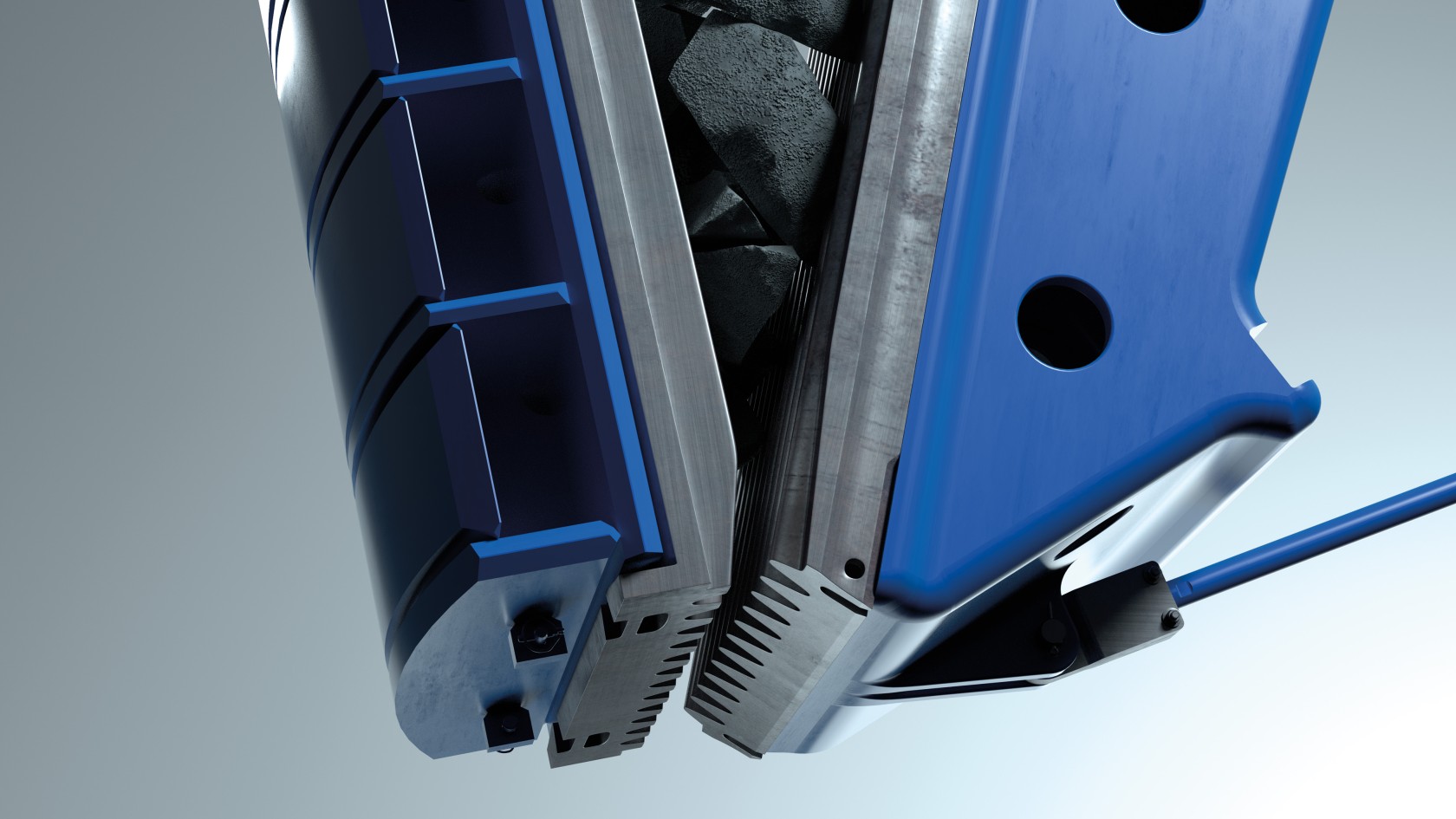

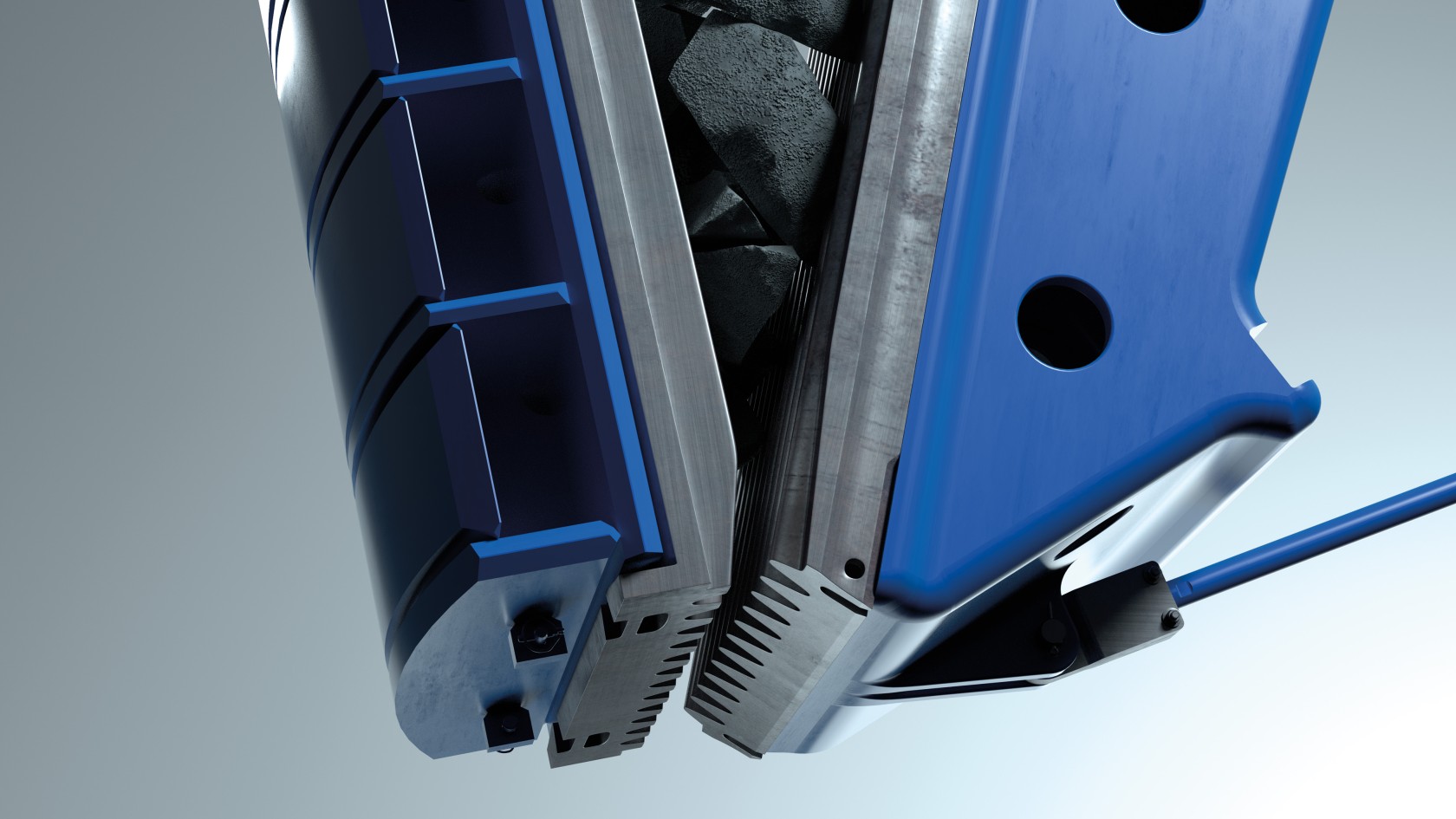

KLEEMANN crushing tools for jaw crushers

Crushing tools from KLEEMANN are made of special hard manganese steel which guarantees a long service life. The shape of the crusher is optimised for the lowest possible wear. A flattened transition from the prescreen and/or the feeding chute into the crushing chamber allows the material to be tipped into the crushing chamber without any obstacles. Thanks to the wide, raised, movable crusher jaw, the material cannot rest on top and less congestion occurs.

The generously sized material tunnel, easily accessible from the side, additionally prevents blockages. Result: High throughput combined with high reliability.

| Shape | Application | Series code | Version | Material specification |

|---|---|---|---|---|

|

RT-BITE (regular teeth) |

Low to medium abrasive natural stone |

MC 100 MC 100 EVO MC 110 MC 110 EVO MC 120 MC 120 PRO MC 125 MC 110 EVO2 |

RT-BITE.18 | MnCr 18.2 |

| RT-BITE.20 | MnCr 20.3 | |||

| RT-BITE.24 | MnCr 24.3 | |||

|

FT-BITE (flat teeth) |

Abrasive natural stone |

MC 110 EVO MC 120 PRO MC 110 EVO2 |

FT-BITE.18 | MnCr 18.2 |

| FT-BITE.20 | MnCr 20.3 | |||

| FT-BITE.24 | MnCr 24.3 | |||

|

ST-BITE (sharp teeth) |

Rounded material (less abrasive) |

MC 100 EVO MC 110 EVO MC 110 EVO2 |

ST-BITE.18 | MnCr 18.2 |

|

MT-BITE (multitype-teeth) |

Special design for crushing hard stone |

MC 110 EVO MC 110 EVO2 |

MT-BITE.18 | MnCr 18.2 |

| * Available only for MC 110 EVO, MC 110 EVO2, MC 120, PRO crushers |

| Shape | Application | Series code | Version | Material specification |

|---|---|---|---|---|

|

RT-BITE (regular teeth) |

Building rubble & recycling / rounded material (abrasive) |

MC 100 MC 100 EVO MC 110 MC 110 EVO MC 120 MC 120 PRO MC 125 MC 110 EVO2 |

RT-BITE.18 | MnCr 18.2 |

| RT-BITE.20 | MnCr 20.3 | |||

| RT-BITE.24 | MnCr 24.3 | |||

|

WT-BITE (wavy-teeth) |

Recycling / cohesive material |

MC 110 EVO MC 110 EVO2 |

WT-BITE.18 | MnCr 18.2 |

| * Available only for MC 110 EVO, MC 110 EVO2, MC 120, PRO crushers |

| Recommended uses | |||||||

|---|---|---|---|---|---|---|---|

| Shape | Final product grain size | Feed material | |||||

| Hard rock |

Soft and medium-hard stone |

Gravel | Building rubble / recycling |

Slabby, medium-hard stone |

Recycling Cohesive material |

||

|

RT-BITE (regular teeth) |

> 60 mm | + | ++ | ++ | ++ | ++ | - |

|

FT-BITE (flat teeth) |

> 60 mm | ++ | + | + | + | - | - |

|

ST-BITE (sharp teeth) |

< 60 mm | - | + | ++ | + | ++ | - |

|

MT-BITE (multitype-teeth) |

> 60 mm | ++ | - | - | - | - | - |

|

WT-BITE (wavy teeth) |

- | - | - | - | - | ++ | |

| ++ Highly recommended | + Recommended | - Not recommended | |||||

| Shape | Wear volume |

|---|---|

| FT-BITE | 135% |

| MT-BITE | 109% |

| RT-BITE | 100% |