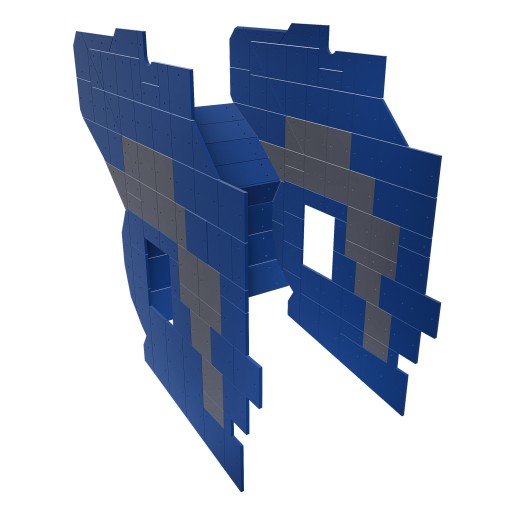

KLEEMANN wear linings

| Wearing plate | Specification | Application |

|---|---|---|

| KRS.40 | Hardness: up to 430 HV | KRS.40, which provide high impact resistance, are highly recommended for materials with low abrasiveness, for example when crushing limestone or recycling mixed rubble and concrete. |

| KRS.50 | Hardness: up to 530 HV |

KRS.50 wear plates are recommended for crushing stone/rocks with medium abrasiveness and recycling. |

| KRS.60 | Hardness: up to 600 HV |

KRS.60 wear plates are particularly suited for crushing extremely abrasive materials and feed materials with uncrushable content (e.g. steel). |

| KRS.HW | Hardness: ~740 HV (hardfacing welded) |

KRS.HW wear plates are recommended when high abrasive wear is expected. The valuable crusher housing is completely lined with particularly wear-resistant plates to protect it against damage. Wear and tear within the housing can vary considerably during the crushing process. KLEEMANN offers a range of special hardfacing welded plates that extend replacement intervals and reduce wear-related costs. These assure you considerably longer service life than the standard plates from KLEEMANN. |