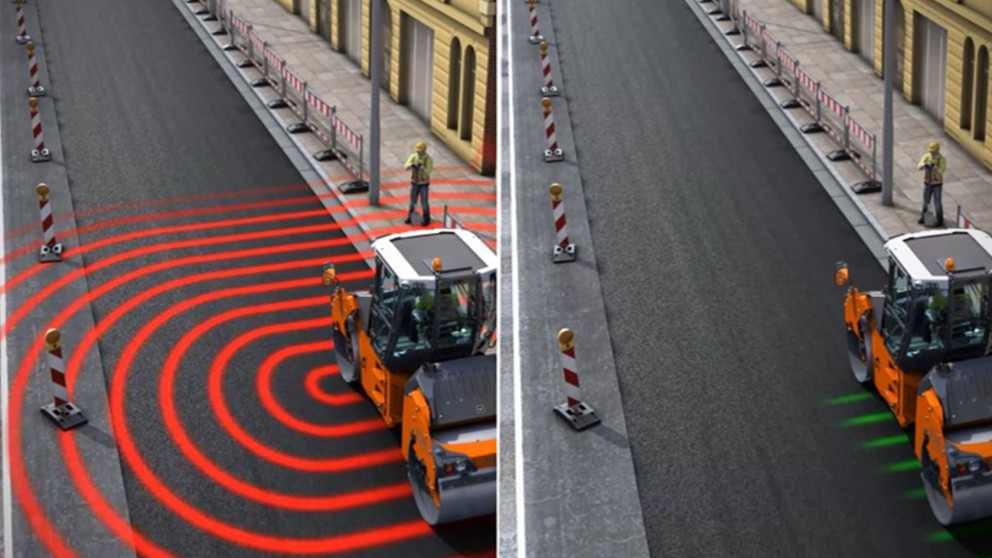

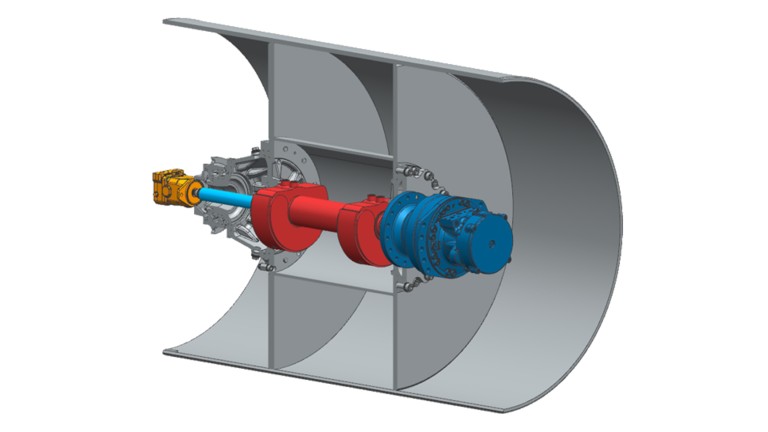

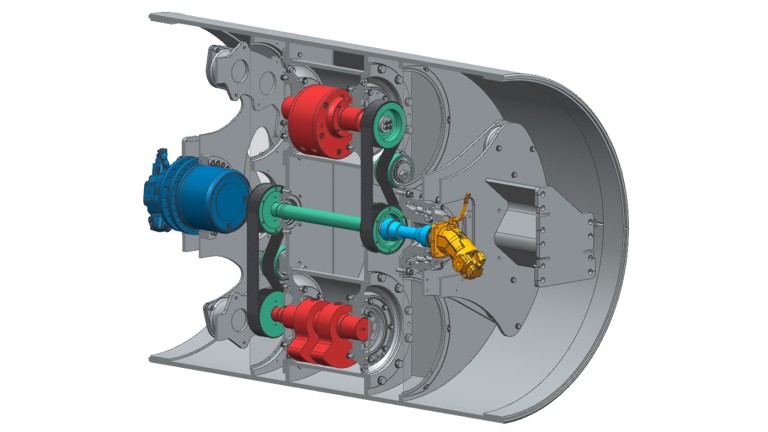

Oscillation generates significantly lower vibratory stresses. (see illustration, right). The stress levels it causes are only up to 10 per cent of those caused by vibration (see illustration, left). Oscillating drums do not use up their energy in the creation of undesired vibration in the surrounding area, but transmit it directly into the material to be compacted - precisely where the energy is needed. Minimised vibration guarantees a longer service life of the machine and provides optimal comfort for the operator.

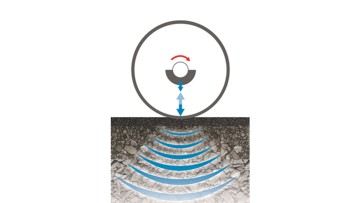

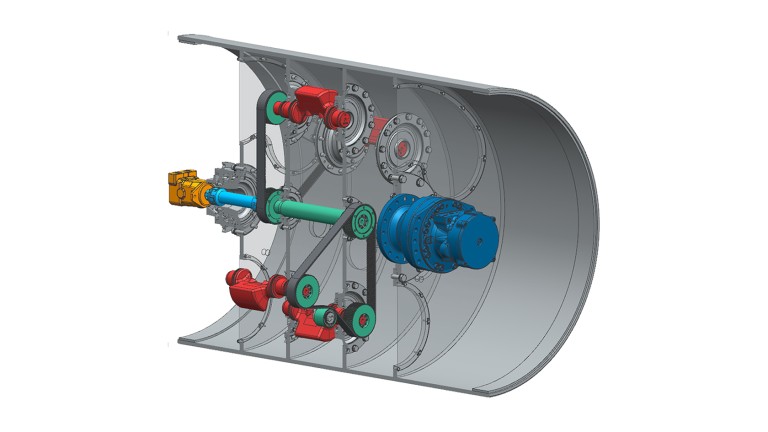

The oscillation system developed by HAMM is not based on complicated mechanical control mechanisms, but relies entirely on the laws of physics. The amplitude value adapts automatically to the stiffness of the substrate. This means that the amplitude decreases continuously in inverse proportion to the increase of soil stiffness. The energy transferred into the soil therefore increases to the same extent as the amplitude decrease.

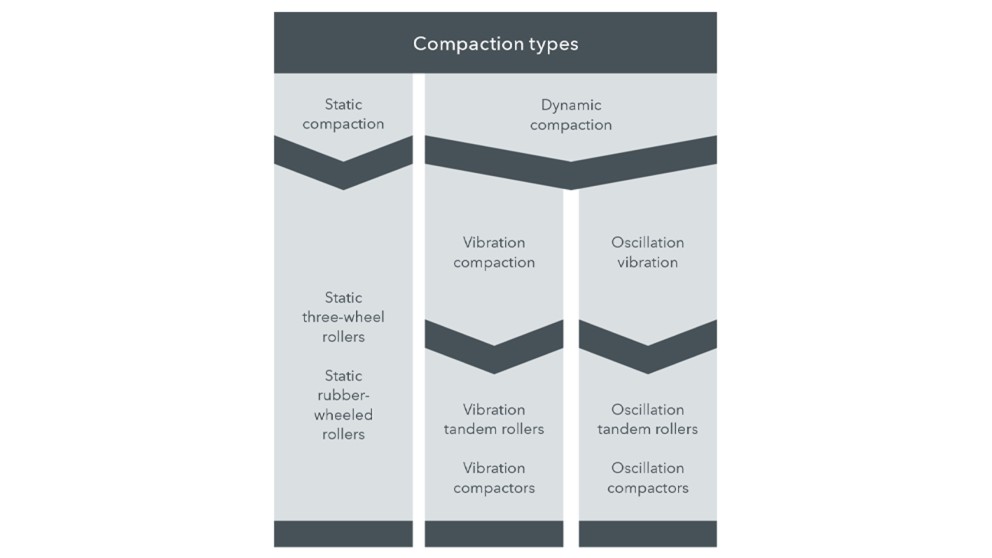

The following video illustrates the various different types of compaction: