Conveyor

The enormous range of original spare and wearing parts for conveyors available from VÖGELE enables you to replace the entire mix conveying system.

The floor plates ensure ideal conveying of the paving mix from the hopper to the rear part of the machine.

The outer (edge guard) and middle plates (centre guard) protect the conveyor chains from the mix and thus ensure long service life of the conveyor chain. Due to their compact dimensions, the MINI Class small pavers require only one conveyor chain.

(optional)

VÖGELE offers the heavy-duty kit as an optional accessory.

We recommend the use of the heavy-duty kit when the paver is frequently used for paving road beds with mixes such as CTB. This counteracts increased wear on components due to the particular properties of the mix.

The conveyor drive shafts are designed and constructed for efficient and powerful material transfer.

Manufactured from heavy-duty material with minimal tolerances, the drive shafts achieve extremely high utilisation rates, even in continuous operation.

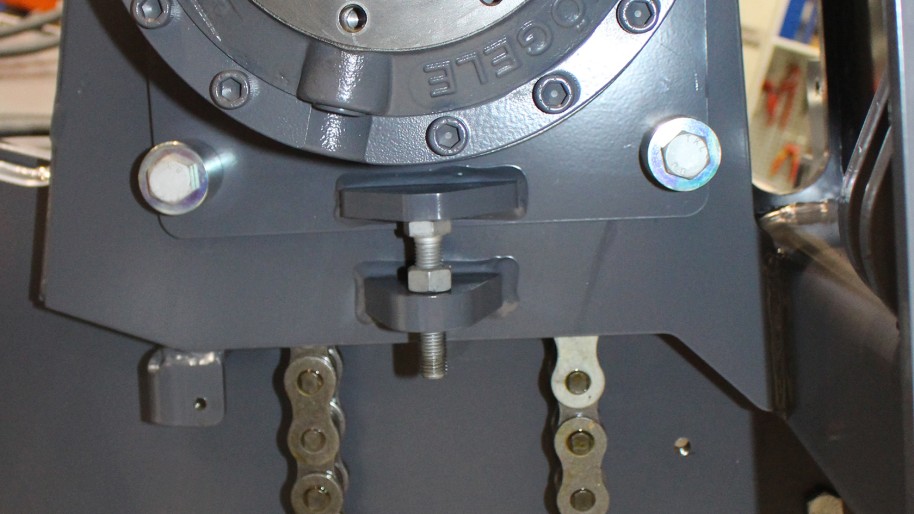

The task of the return rollers with roller bearings is to guide the conveyor chain at the front of the machine and turn it downwards for return to the drive sprocket.

The bearings of the return rollers consist of encapsulated and sealed ball bearings and are maintenance-free.

Conveyor maintenance

The conveyor chain is the key component of the conveying system. It consists of two chains connected to one another by conveyor chain rods.

The conveyor chain transports the asphalt mix from the material hopper to the paving screed.

The conveyor chains can be reversed to prevent mix falling out of the rear of the conveyor tunnel and soiling the ground when relocating the machine. When this is done, the mix is transported a short way back to the material hopper.

Regularly check whether the conveyor chain is correctly tensioned and adjust it if required. A correctly tensioned conveyor chain may not be under tension on its loose side at any time during movement. Excessively high tension of the conveyor chain causes irregular running or knocking.