Current special campaigns

Milling drum accessories

Genuine milling drum accessories from WIRTGEN: buy reliable, long-life ejectors and toolholders online.

Genuine WIRTGEN toolholders are designed for a long service life and low maintenance requirements.

Our ejectors ensure that the material is smoothly and efficiently discharged from the milling drum housing.

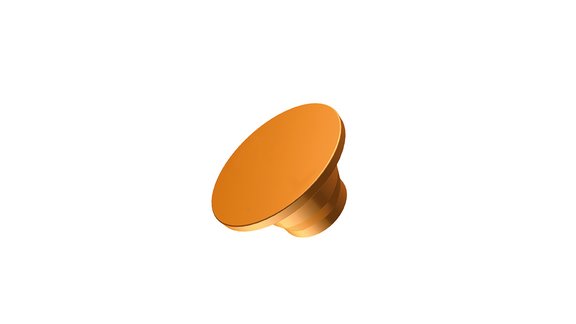

Ejectors

Genuine WIRTGEN ejectors are perfectly compatible with all components involved in the milling process and ensure that material is efficiently discharged from the milling drum housing. In addition to our type 1 ejectors, the premium type 2 ejectors feature an enhanced conveyor unit for less wear on the milling drum tube and the cutting components.

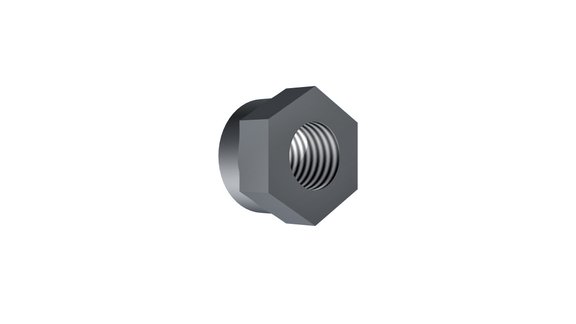

Toolholder

A high degree of operational reliability and extremely wear-resistant cutting tools play a critical role in precise and productive milling operations. The robust WIRTGEN toolholder systems are fitted with cutting tools that can be replaced quickly and easily right on the construction site.

Due to possible technical changes, always refer to the information in the instruction manual.

Campaigns are not available in all countries – please contact your local sales and service organisation if you have any questions.