GENERATION Z²

Highlights

GENERATION Z² round-shank picks are distinguished by unique product properties that above all enable users to significantly reduce their operating costs. Thanks to their adapted shank design and optimised carbide tip geometry with a reinforced carbide base, the picks in this product line are designed to withstand high impact loads and are therefore the ideal solution for recycling and soil stabilisation applications. The relatively large steel body volume compared to conventional picks and the reinforced wear plate deliver the longest possible service life for tools and optimum protection for the top part of the toolholders in applications involving abrasive materials.

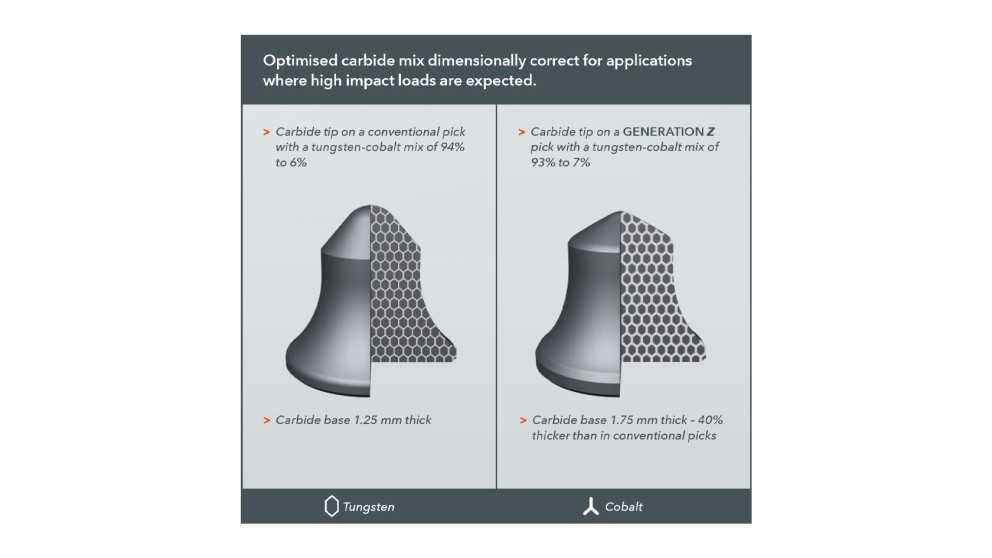

Carbide mix:

In combination with the reinforced carbide base, the carbide mix with a high cobalt content of 7% ensures outstanding durability of the carbide, even in situations with extremely high impact loads. In view of these unique properties, the universal picks of the GENERATION Z² series are the ideal choice for all cold recycling and soil stabilisation applications.

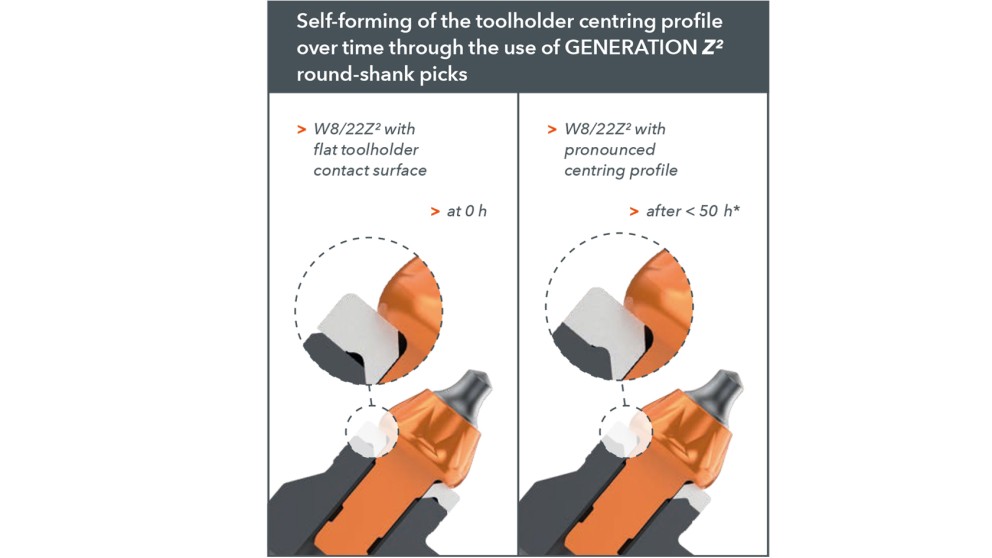

The interplay of round-shank picks and the top part of toolholders

GENERATION Z² universal round-shank picks also have a positive effect on the wearing of the upper parts of tool holders. The innovative centring function reduces lengthwise wear. The service life can be increased by over 25%, especially in the case of heavy-duty applications such as pulverisation.

Recommended uses

Soil stabilisation applications

Cohesive soils/milled material generally contain abrasive (grinding) materials that flow around the carbide tip and the pick head during the cutting process. In such cases, wear to the steel body dominates and therefore limits the service life of the pick. Here, the carbide tip plays an important role by deflecting material away from the steel body (pick head) and reducing its wear.

In the case of soils interspersed with rocks or boulders, it is advisable to use round-shank picks with a cylindrical tip (or a W6C tip). In this case, the fracture toughness of the carbide tip is the decisive factor, as suddenly occurring high impact forces must be deflected.

When the shanks of round-shank picks are subjected to extreme impact stresses due to larger rocks and boulders, the top parts of the toolholder system can be replaced to allow the use of round-shank picks with a shank diameter of 25 mm.