Track rollers

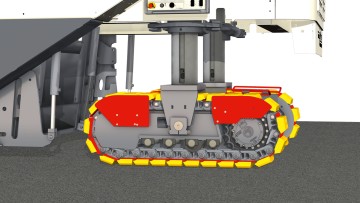

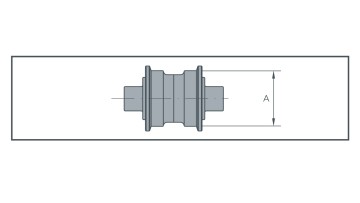

The track rollers of tracked machines (e.g.: excavators, road milling machines, etc.) bear the full weight of the machine. They are designed and constructed to bear the full weight of the machine in standard operating procedures without problems and to efficiently dissipate the heat generated by continuous loading to protect all components such as bearings, seals etc. It is a well known fact that WIRTGEN road milling machines achieve high advance rates, even at greater milling depths. In doing so, the crawler units of road milling machines are exposed to extreme loads, so, in view of this, WIRTGEN utilises high-quality track rollers designed and manufactured exclusively for the individual machine models.

During their development, particular emphasis was placed on optimal performance without maintenance.As a consequence of this, all current tracked construction machine models from WIRTGEN are fitted exclusively with pre-stressed track rollers with roller bearings.

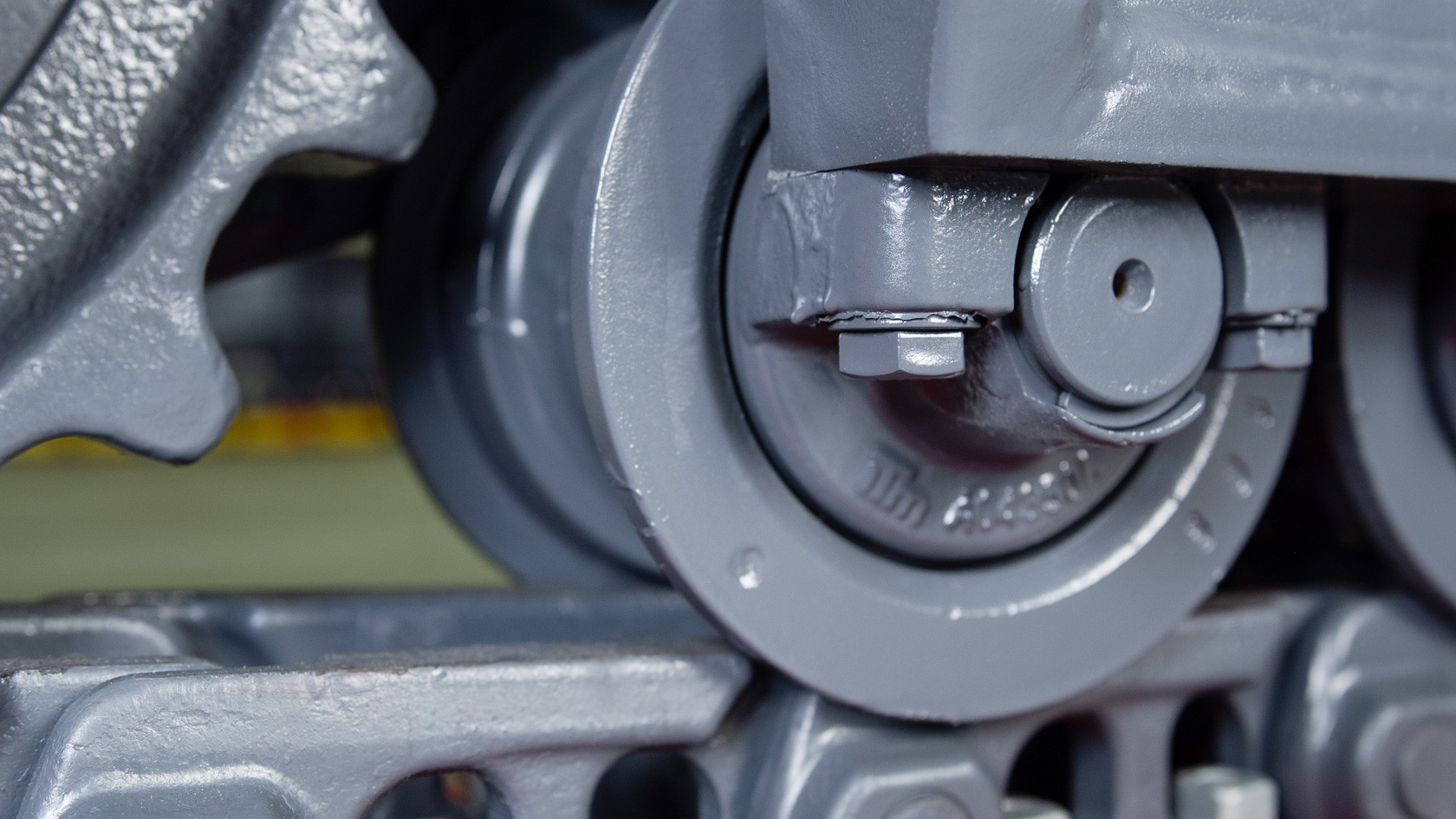

Thanks to their construction concept, WIRTGEN roller bearing mounted track rollers are able to withstand significantly higher loading stresses. For years now, they have been manufactured with especially resilient, premium materials for the slide ring seals and bearings, in order to minimise the risk of leakage and extend their service life.

Sliding bearing track rollers of insufficient quality are prone to damage, particularly in the case of prolonged periods machine travel at high speeds. Such damage can result in leaks and loss of oil. This leads to defective lubrication of the bearings and the eventual failure of the track rollers. A significant lack of oil in the track roller means that the bearings inside can no longer rotate around the axle, resulting in a seized roller and potentially serious damage.

Wear on track rollers

Leakage is the reason generally given to justify the premature replacement of track rollers.However, a distinction must be made between actual leaks and minor leakage. Due to the sliding bearing seal, the leakage of small amounts of oil is perfectly normal and, in industry jargon, is commonly referred to as ‘sweating’. This absolutely typical occurrence in the case of sliding bearing seals cleans the lapped surfaces of the sliding rings and prevents the ingress of dirt into the roller or sliding bearings in the track roller.

Track rollers with leaking or seized bearings should be replaced as soon as possible to avoid damage or wear to other track unit components, e.g. the track chain. This is because the blocked rotation of track rollers can lead to rapid wear on the track chains, as it increases the frictional forces on the track roller casing and the contact surfaces of the chain links. At the same time, a pressure increase in the hydraulic system of the advance drive will be observed, since the necessary energy to propel the track unit increases. High loading stresses will eventually also affect other mechanical components, such as for example, on the tooth flanks of the drive sprocket or the bushes that protect the chain pins.

Uneven loads on the track rollers can lead to premature failure. A typical example of such loading stresses occurs when the machine is working with track rollers with different degrees of wear due to not being changed in sets during maintenance.

Repeated rolling over kerbs leads to asymmetrical loading on the track rollers.