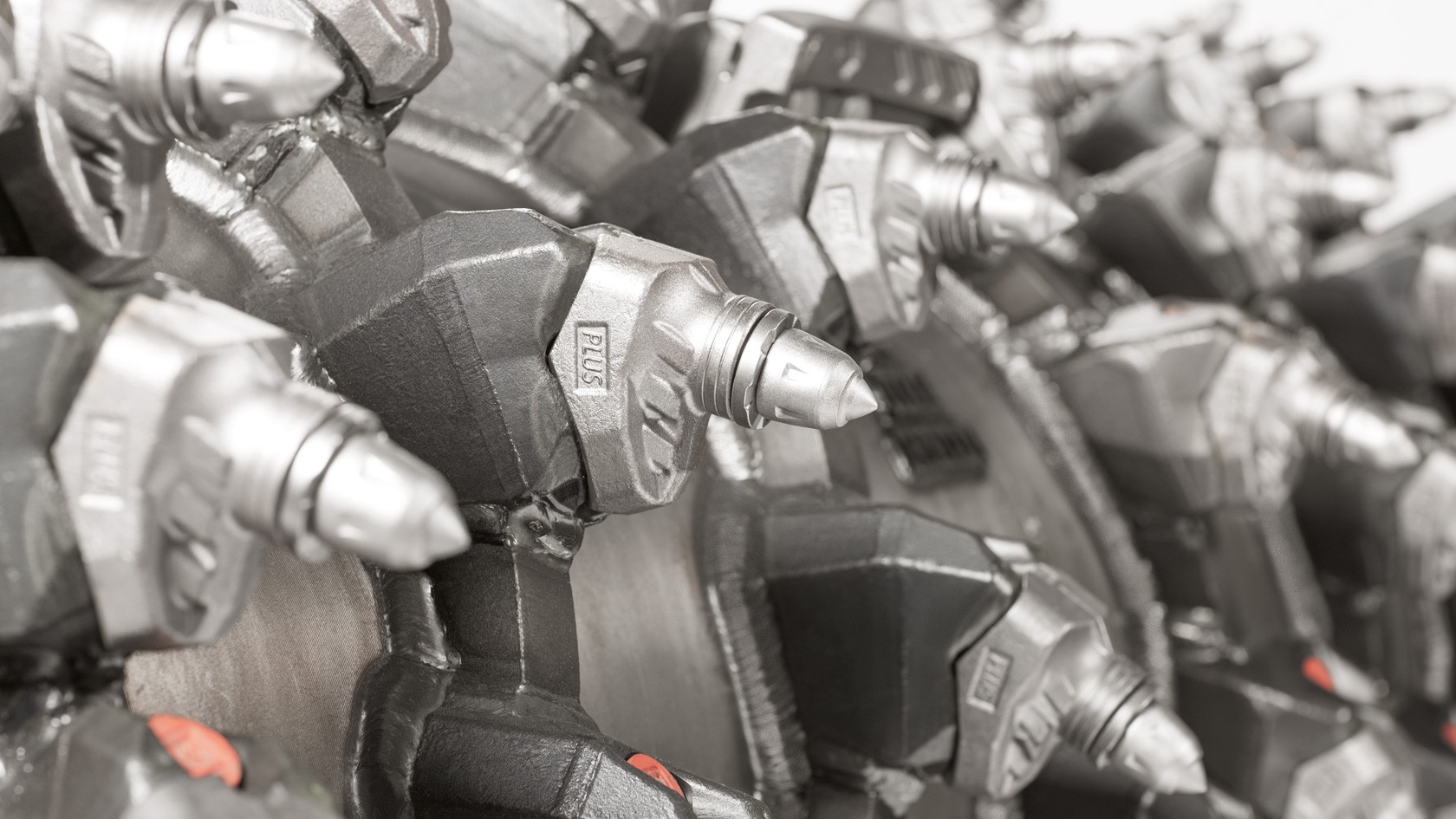

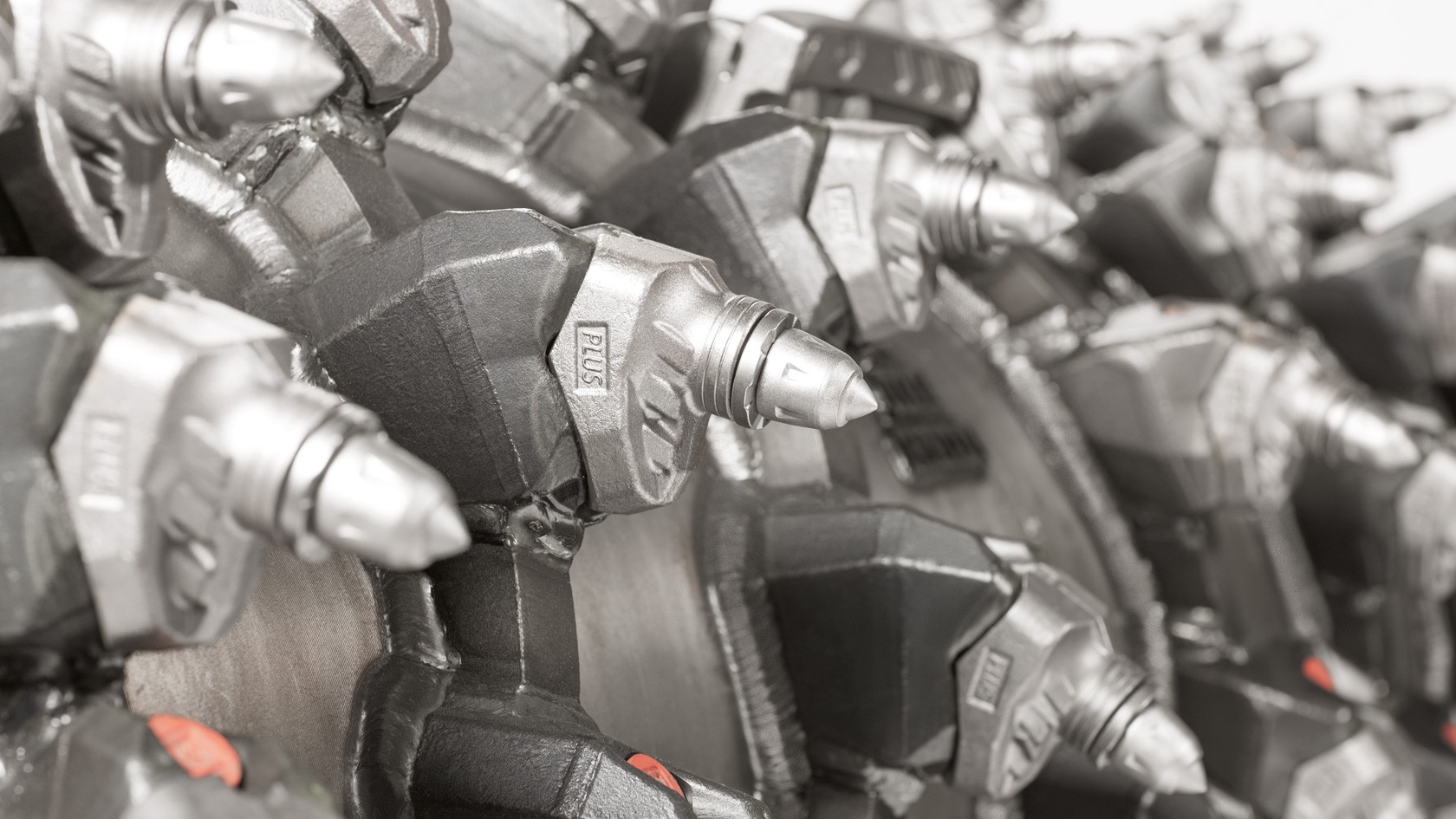

GENERATION C²

GENERATION C² round-shank picks are specially designed for milling concrete and asphalt with ECO Cutter milling drums. In combination with the shortened clamping sleeve, the optimised pick shank ideally conducts the milling forces to the top part of the pick holder and relieves the forces acting on the clamping sleeve. The shortened clamping sleeve secures the round-shank pick precisely and permanently in the pick holder. The revised shank geometry further increases resistance to fracturing,

All in all, GENERATION C² round-shank picks offer optimised carbide distribution with improved cutting performance and increased resistance to fracturing. The solid steel body geometry improves chip removal and extends their service life.

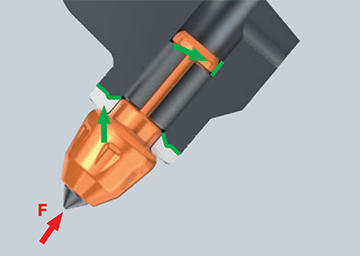

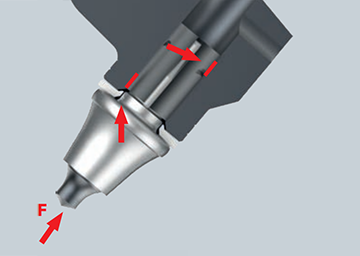

Wear plate and clamping sleeve geometry

The unique grooved profile of the wear plate with its innovative centring function reduces wear and increases the service life of round-shank picks and pick holders. In addition, the wear plate has been upgraded to heavy duty and its shape has been optimised to provide maximum protection of the pick holder

The new, short clamping sleeve geometry minimises mechanical loading on the clamping sleeve and assures optimal clamping force throughout the entire service life. The wear plate geometry, with the grooved profile on the underside, is an essential feature of GENERATIONC² round-shank picks and enables positive locking of the pick in the pick holder.

The transmission of force from the pick into the top part of the pick holder takes place via the WIRTGEN wear plate with the centring groove and the optimised pick shank with the shortened clamping sleeve. In contrast to the case with conventional picks, this reduces the load on the clamping sleeve and increase the service life. Thanks to the minimal play and ideal centring of the pick, this also increases the service life of the top part of the pick holder.

Optimised pick centring and reduced loading on the clamping sleeve

Comparison between a GENERATION C² round-shank pick and a conventional pick: