Idlers

Wear on idlers and idler guides

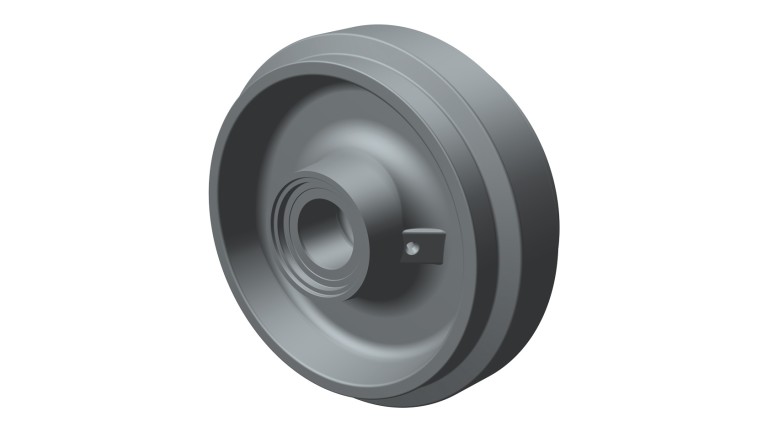

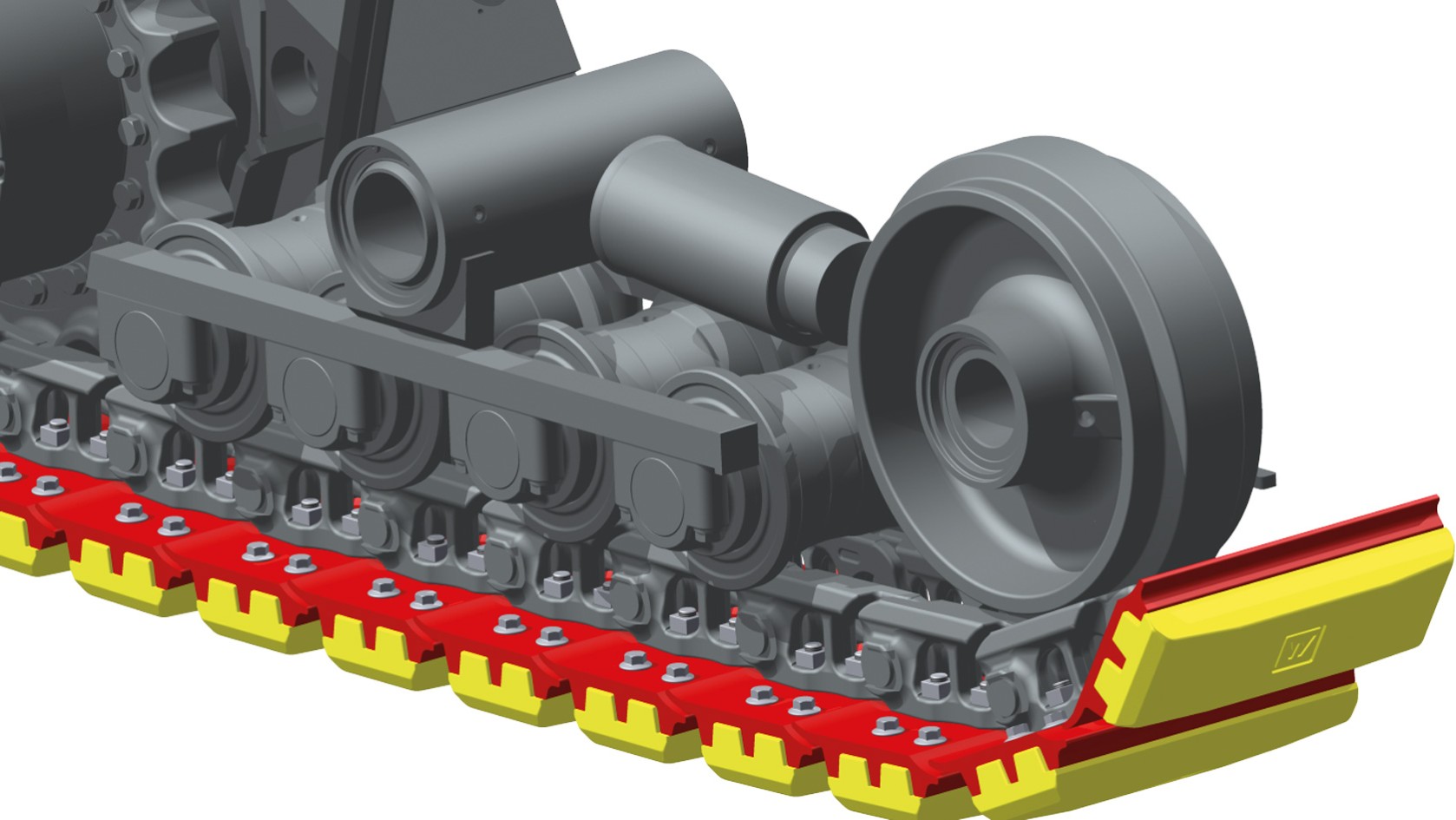

During travel, the tension of the track chain is maintained by a spring-, grease- or hydraulically-tensioned cylinder located above the idler and the idler guide. Wear is accelerated by the combination of caked dirt and/or too high or too low tensioning force from the cylinder and the friction generated by the track chain rolling over the idler wheel.

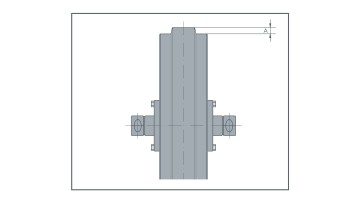

If wear dimension A for the idler is exceeded, the bushes of the track chain can slide over the idler and significantly reduce its potential service life.

If the idler guide at the end of the track unit bracket projects outside the undercarriage frame, the first step to take is to check the wear on the track chains against the wear dimensions listed on the previous pages, because, as a rule, an excessively worn track chain must be assumed. If the track chains are not changed in good time, this leads to increased vibration of the track unit, since the idler guide is not mounted with its contact surfaces completely in the frame. Such vibration can lead to damage to the idler bearing.

Due to the relative movement of the idler bracket in the steel construction of the undercarriage frame, this leads to wear not only on the idler bracket itself, but also on the undercarriage frame. If the machine has been in use for many years, the play in the idler should be checked either during fitting or replacement, in order, if necessary, to rework the steel frames before the renewed assembly of all components such as the track chains, tensioning cylinders with idlers, etc.