Track chains

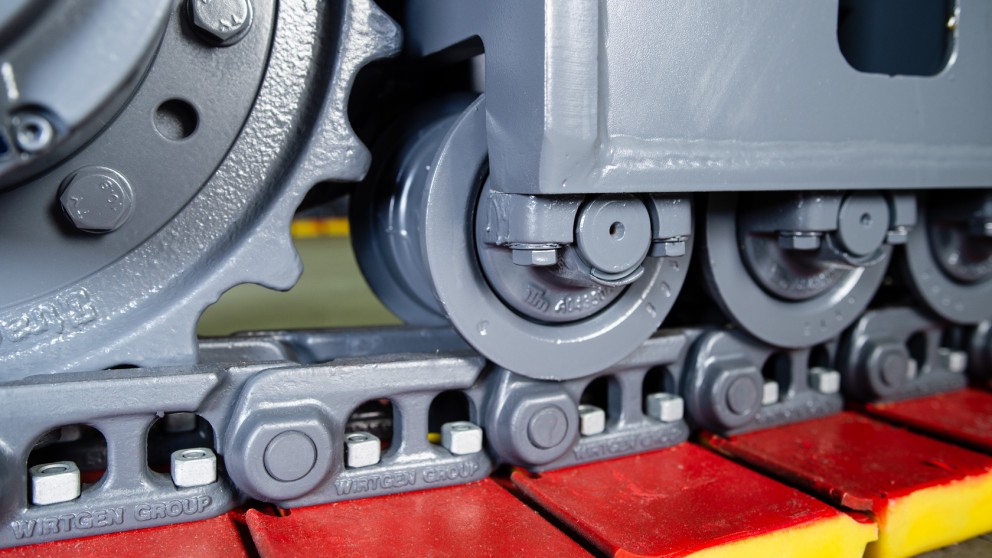

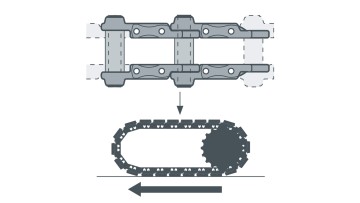

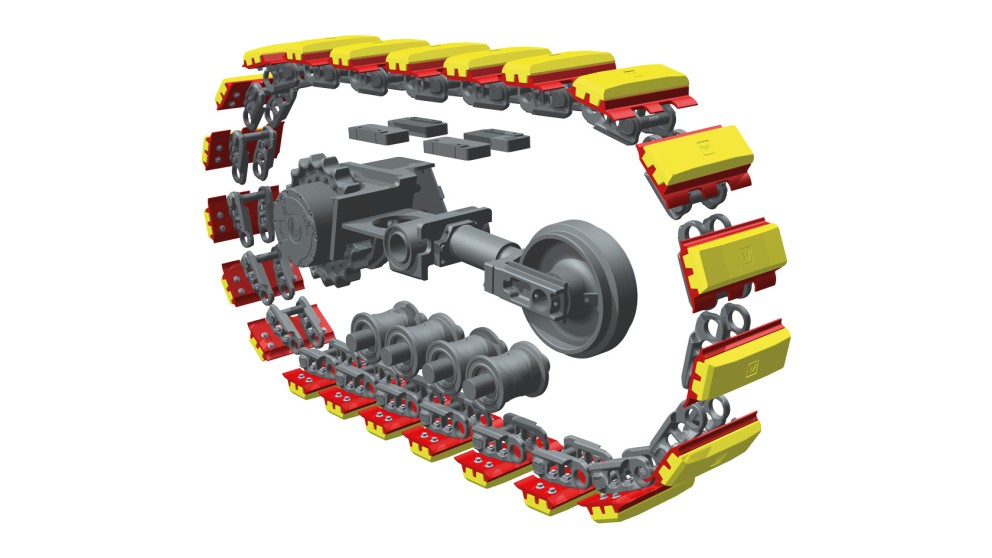

Track chains consist of chain link segments, which are connected to each other by bushes and pins. The drive sprockets drive the track chains, which in turn advance the machine in the desired direction of travel. The chain tension must be sufficiently high to ensure that the teeth of the drive sprocket securely engage in the track chain. Depending on the loading on the track chains by the operating weight of the machine and its maximum possible advance speed, WIRTGEN GROUP machines use not only dry, but also lubricated track chains.

In the case of lubricated chains, there is a lubricant between the bushes and pins that minimises friction between these components and, depending on the application, lengthens the service life of the track chains. The chain tension is created by a tensioning system. The necessary tension is provided and maintained either by a spring-grease tensioning cylinder or a hydraulic tensioning cylinder.

The dimensions and materials of all genuine WIRTGEN GROUP track chains are precisely matched to the drive sprockets, track pads and track rollers. They effortlessly withstand even the toughest continuous stresses in everyday use.

Wear on track chains

In order to keep wear on track chains to a minimum, it is essential to ensure that they are always correctly tensioned.

The chain tension should therefore be regularly checked, especially in the case of grease tensioned crawler units.

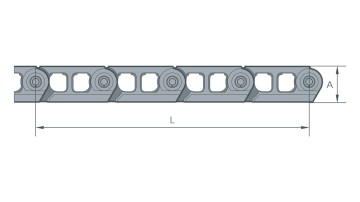

Track chains stretch over time. The degree of stretch can be checked with the wear dimensions shown in the table. The track chain is also precisely matched to the tooth profile of the drive sprocket This profile changes in the course of the operating time. If either the drive sprocket or track chain need to be replaced, always replace both at the same time.