Filtering

Filtering processes separate or clean substances. Only dirt with a certain particle size measured in micrometres is allowed to pass through the filter. The interaction between genuine filter elements and lubricants from the WIRTGEN GROUP prevents damage caused by contamination and, at the same time, increases machine utilisation rates.

Particularly in the case of construction machines that work continuously under heavy loads, the filters used must be perfectly matched to the relevant construction site requirements, i.e. appropriately designed. Although fitting WIRTGEN GROUP machines with non-OEM parts appears, on the face of it, to be cheaper, experience has shown that this often leads to considerable complications, e.g.:

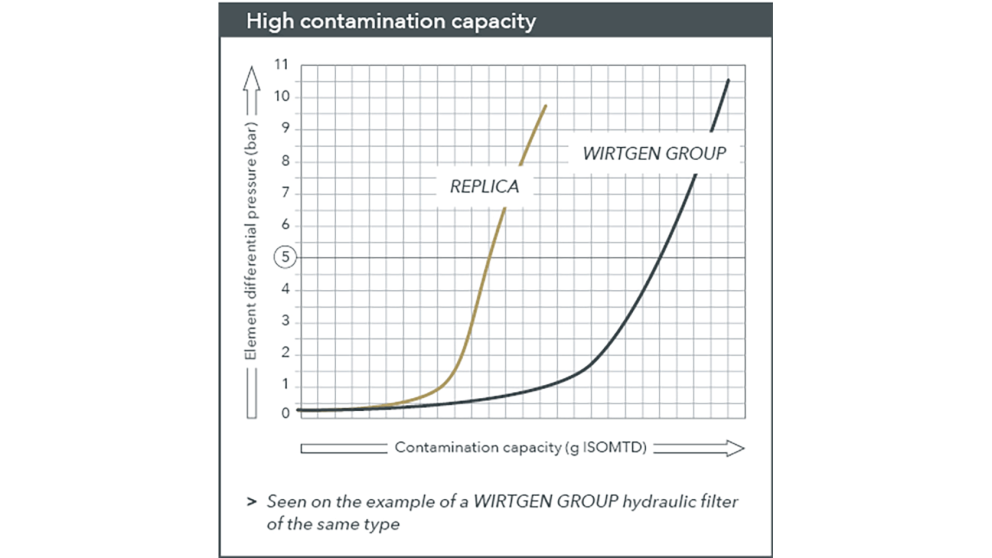

In the case of all filter types, it is not only the dirt holding capacity that is decisive, but also the resulting pressure differences. In the case of non-OEM products, this may lead to an increase in the number of blockages as the degree of contamination increases.

HIGH DIRT HOLDING CAPACITY FOR A LONG SERVICE LIFE AND LOW OPERATING COSTS:

At the time of filter replacement (when a differential pressure drop of 5 bar across the filter is reached), the genuine WIRTGEN GROUP filter will have held back significantly more dirt.

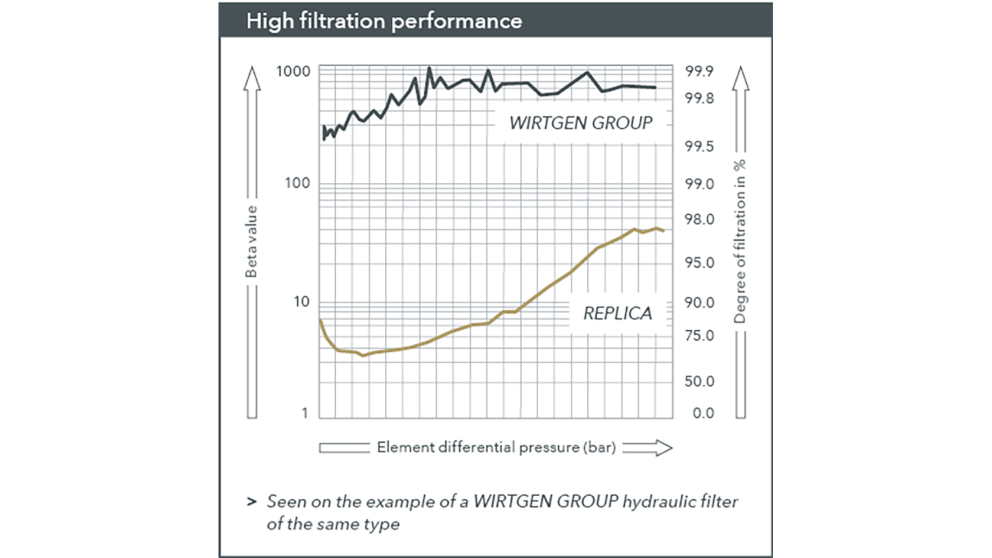

HIGH SEPARATION EFFICIENCY FOR EFFECTIVE COMPONENT PROTECTION AND HIGH OPERATIONAL RELIABILITY:

The separating efficiency of a genuine WIRTGEN GROUP filter is far greater than that of any inferior-quality non-OEM alternative.