PCD milling tools

Highlights

Thanks to the tool geometry and materials, PCD milling tools are the perfect choice for applications from surface course rehabilitation to (micro) fine milling. They have a highly wear-resistant tool tip made of poly-crystalline diamond (PCD) with an extremely long service life. The only slight incidence of lengthwise wear leads to extreme evenness of the milled surface and a constantly high machine advance rate. Depending on your application, PKD milling tools might be a practical supplement to your existing programme of round-shank picks with conventional carbide tips.

PCD milling tools:

As a cutting material, poly-crystalline diamond (PCD) is the ideal solution for milling homogeneous asphalt packages in which no abrupt impact load peaks are to be expected. In particular, PCD milling tools are a cost-effective alternative for surface course rehabilitation to depths of up to 8 cm and in the area of (micro) fine milling of asphalt surfaces.

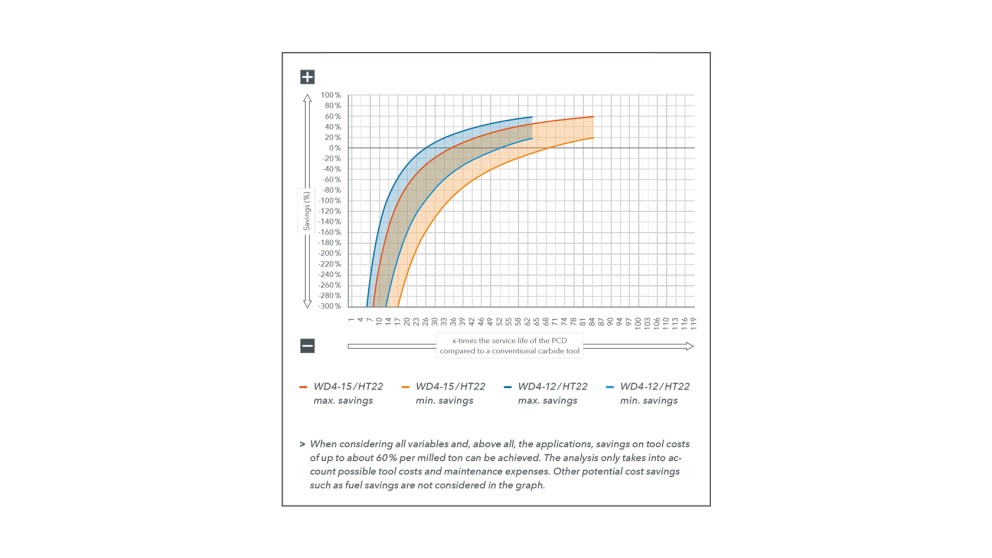

PCD performance rating

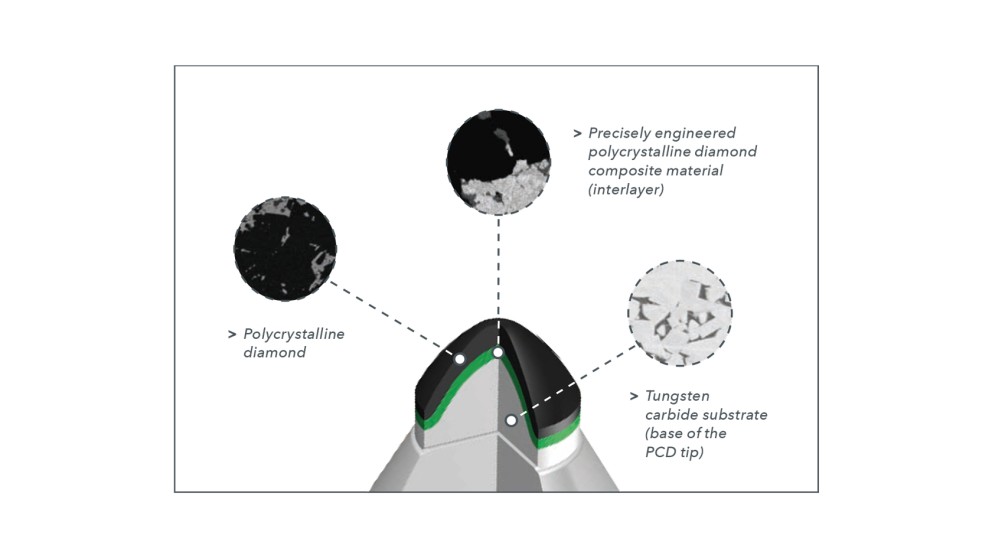

Schematic representation

of a PCD tip