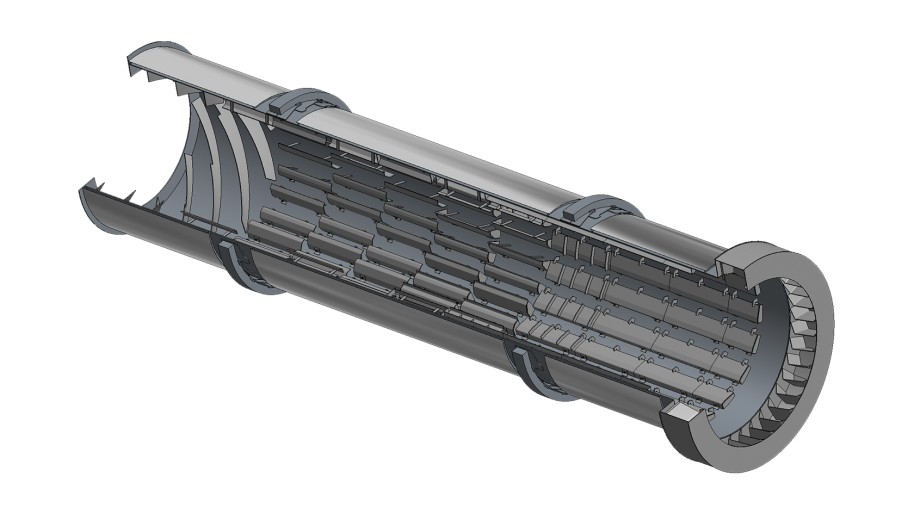

Lifter plates | Dryer and recycling drums

Influencing parameters such as the plant location, type of rock, material moisture, material temperature and fuel type determine whether lifter plates are used.

Dryer drums are compact, robust and easy to maintain. Made by Benninghoven.

Lifter plate highlights

Outstanding material quality with maximum flexibility

First-class drying

Continuous temperature optimisation

Built-in fire protection

Easy to replace