Wirtgen Group lubricant types

For ensuring optimum engine performance: Engine oils prevent direct metal-to-metal contact between individual components, reduce friction, and therefore play a decisive role in minimising engine wear. They also contribute to the sealing and cooling of the pistons, thereby promoting higher compression, which in turn ensures higher engine performance. In short: engine oils are lubricants for maintaining the engine and reducing the stresses it is subjected to.

Coolants are mixtures of substances which are used for the dissipation of heat and therefore protect components against overheating.

For efficient power transmission: As hydraulic fluids, the purpose of hydraulic oils is to transmit the hydraulic power from the pump to the engine or cylinder with minimal energy loss. At the same time, they lubricate moving parts, protect against corrosion, and transport contaminants out of the hydraulic system. Hydraulic oils must, however, be resistant to ageing and pressure. They also need to demonstrate outstanding wetting and adhesion properties.

The most frequently used hydraulic fluids are based on mineral oils treated with appropriate additives. The term hydraulic oil is used for such specially formulated oils. Hydraulic oil requirements are regulated in ISO 6743/4 under the codes HL, HM, and HV (in Germany, the codes HL, HLP, HVLP are commonly used in line with DIN 51524).

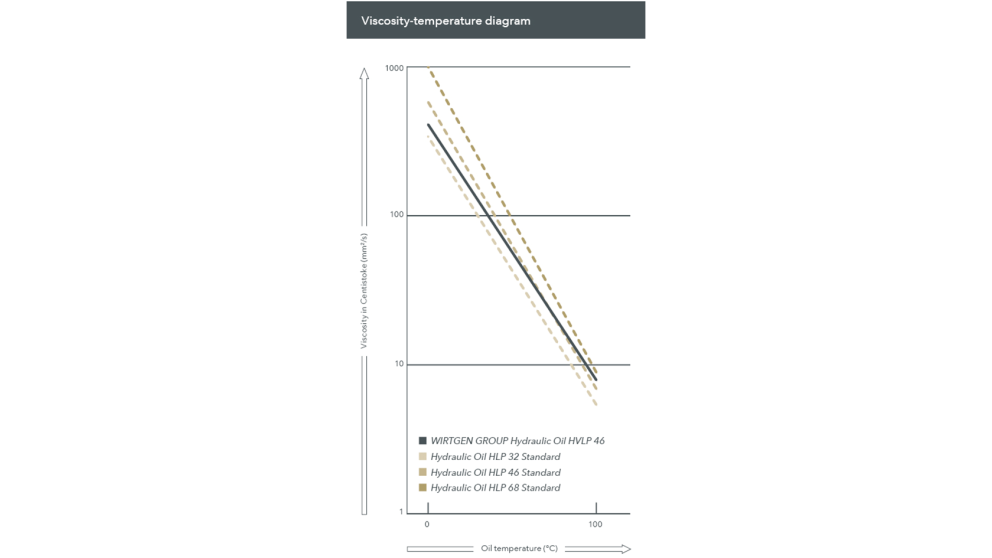

WIRTGEN GROUP HVLP oils contain additives for increased corrosion protection, resistance to ageing, reduction of fretting wear in the mixed friction range, and for the improvement of the viscosity/temperature ratio (higher viscosity index), as well as the suppression of foaming.

The ISO (International Organization for Standardization) classifies hydraulic oils according to their viscosity.

The characteristic curve for the WIRTGEN GROUP multigrade hydraulic oil is significantly flatter, i.e. the oil is affected less by temperature-variations. At an oil temperature of 100°C, it can clearly be seen that the viscosity value is much more stable than that of a standard HLP hydraulic oil. The WIRTGEN GROUP Hydraulic Oil HVLP 46 has a viscosity of 7.9. In comparison, the viscosity of the standard hydraulic oil is only 6.9.

This shows that the multigrade oil has a higher viscosity at high temperatures than a standard oil and therefore provides better lubrication. The WIRTGEN GROUP also offers a specially formulated VG 100 hydraulic oil for use at high ambient temperatures such as those encountered in tropical regions. VG 32 hydraulic oils can also be purchased for use in regions with consistently low ambient temperatures.

Ensuring the protection and smooth running of gearboxes: Gear oils protect gearboxes against corrosion, neutralise acids, and prevent typical damage such as pitting (flaking) and fretting (point-fusion with subsequent separation due to mechanical loads). They also guarantee outstanding smooth-running characteristics in mechanical components such as gear wheels, bearings, friction clutches, or braking systems. The lubricant has to withstand extreme temperature fluctuations, high partial pressures, condensation, as well as dust and abraded contaminants.

In contrast to ACEA, API also issues standards for gear oils. The API GL-5 (Gear Lubricant) is the standard that can currently fulfil the most stringent requirements. The following list provides an overview of gear oils for a variety of applications.

For reliable lubrication of components: Lubricating greases are formulated for the long-term lubrication of roller, sliding, and linear bearings, as well as sliding surfaces, gear wheels, and gear teeth. Greasing provides outstanding protection against corrosion and prevents age-related material fatigue. Greases must remain soft and supple, even at extremely low temperatures. At the same time, they may not become runny or drip at high temperatures.

Lubricating greases are made from a base oil to which thickeners are added. Thickeners, in turn, are special soaps which are, for example, manufactured on the basis of the metals lithium, calcium, aluminium, barium, or sodium. Lubricating greases are also treated with additives that protect mechanical components against wear and corrosion.

The use of different additives results in considerable differences in the properties of lubricants. This explains the large number of lubricants we offer.