WIRTGEN Conveyor unit

In daily use, the primary and discharge conveyors of WIRTGEN cold milling machines quickly, safely and reliably transport highly abrasive materials and enable maximum conveying rates

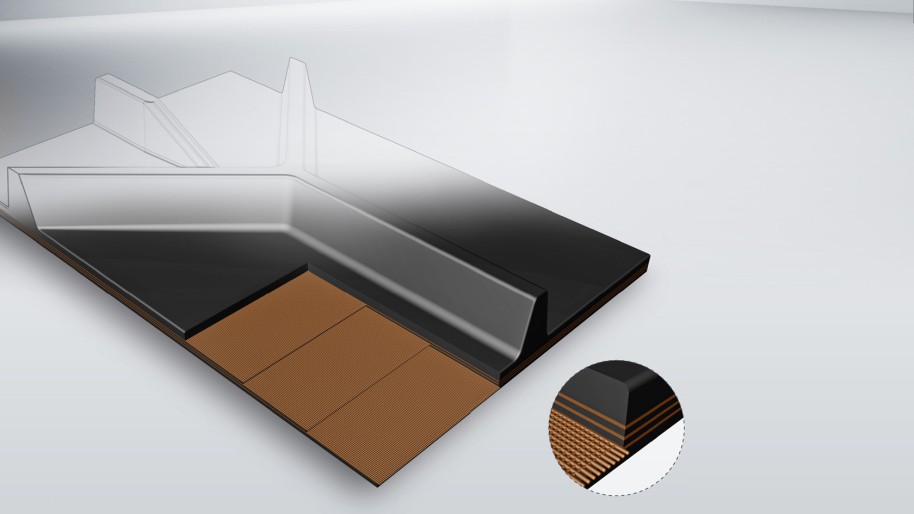

In view of this, all components involved are subjected to enormous demands. In order to assure maximum service life, WIRTGEN manufactures conveyor belts using the hot vulcanisation method. We recommend the use of our hot vulcanised conveyor belts to guarantee reliable feeding and transfer of material.

The high milling performance of WIRTGEN cold milling machines demands reliable offloading of the milled material. The perfect interaction of all components is essential for ensuring maximum reliability and productivity. A decisive role is played not only by the belt itself, but also by the guide rollers, support rollers, drive rollers and return rollers developed especially for the task. These genuine WIRTGEN components all stand out on account of their low-friction properties and high-quality roller bearings. The focus on optimal harmonisation of the individual, high-quality components also contributes to the minimisation of wear on the conveyor unit. This leads to a long service life.