Screening

Quickly and easily order and buy genuine KLEEMANN screen media for your screening needs online now.

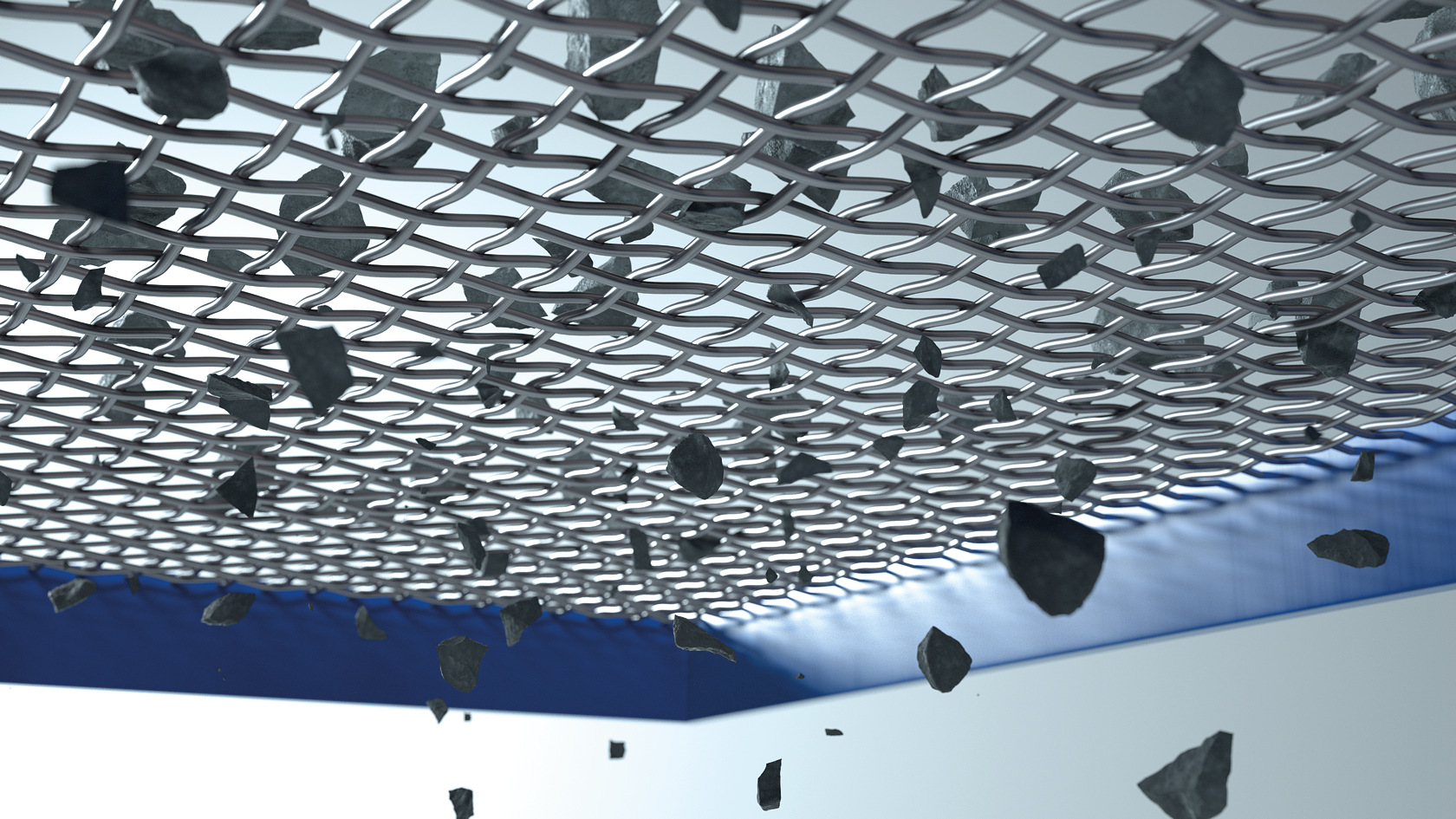

Anti-clogging ropes

Screening sticky material creates caking on the screen linings and thus impedes the further flow of the material. Fitting KLEEMANN anti-clogging ropes helps to avoid unwanted maintenance or downtimes during such applications.

| Light | < 4 mm | Upper deck, middle deck, lower deck |

| Standard | > 4 mm | Upper deck, middle deck, lower deck |

| Light | < 4 mm | Upper deck, middle deck, lower deck |

| Standard | > 4 mm | Upper deck, middle deck, lower deck |

| Standard | > 4 mm | Upper deck, middle deck, lower deck |

| Light | < 4 mm | Upper deck, middle deck, lower deck |

| Light | < 4 mm | Upper deck, middle deck, lower deck |

| Standard | > 4 mm | Upper deck, middle deck, lower deck |

| Standard | > 4 mm | Upper deck, middle deck, lower deck |

| Light | < 4 mm | Upper deck, middle deck, lower deck |

Finger screens

Genuine KLEEMANN finger screens are ideal for screening materials that are hard to separate, such as moist and sticky bulk materials, and when recycling mixed rubble. The separation of flaky/slabby and bulky screenings in scalpers is therefore no problem at all.

| 100 mm | 4 pc. | Upper deck |

| 50 mm | 4 pc. | Upper deck |

| 60 mm | 4 pc. | Upper deck |

| 75 mm | 4 pc. | Upper deck |

| 100 mm | 4 pc. | Upper deck |

| 50 mm | 4 pc. | Upper deck |

| 75 mm | 4 pc. | Upper deck |

| 100 mm | 5 pc. | Upper deck |

| 50 mm | 5 pc. | Upper deck |

| 75 mm | 5 pc. | Upper deck |

Harp screens

Genuine KLEEMANN harp screens are generally recommended for use with moist, sticky materials that are difficult to screen.

| G harp screen/piano wire for MOBISCREEN series | 10 mm | Lower deck - NSE | Screen section, large |

| 2 mm | 2 pc. |

| G harp screen/piano wire for MOBISCREEN series | 2 mm | Lower deck - NSE | Screen section, large |

| 1 mm | 3 pc. |

| G harp screen/piano wire for MOBISCREEN series | 2.5 mm | Lower deck - NSE | Screen section, large |

| 1 mm | 3 pc. |

| G harp screen/piano wire for MOBISCREEN series | 4 mm | Lower deck - NSE | Screen section, large |

| 1.2 mm | 3 pc. |

| G harp screen/piano wire for MOBISCREEN series | 5 mm | Lower deck - NSE | Screen section, large |

| 1.4 mm | 3 pc. |

| G harp screen/piano wire for MOBISCREEN series | 6 mm | Lower deck - NSE | Screen section, large |

| 1.6 mm | 3 pc. |

| G harp screen/piano wire for MOBISCREEN series | 7 mm | Lower deck - NSE | Screen section, large |

| 1.6 mm | 3 pc. |

| G harp screen/piano wire for MOBISCREEN series | 8 mm | Lower deck - NSE | Screen section, large |

| 1.6 mm | 3 pc. |

| G harp screen/piano wire for MOBISCREEN series | 9 mm | Lower deck - NSE | Screen section, large |

| 2 mm | 3 pc. |

| G harp screen/piano wire for MOBISCREEN series | 10 mm | Lower deck - NSE | Screen section, large |

| 2 mm | 2 pc. |

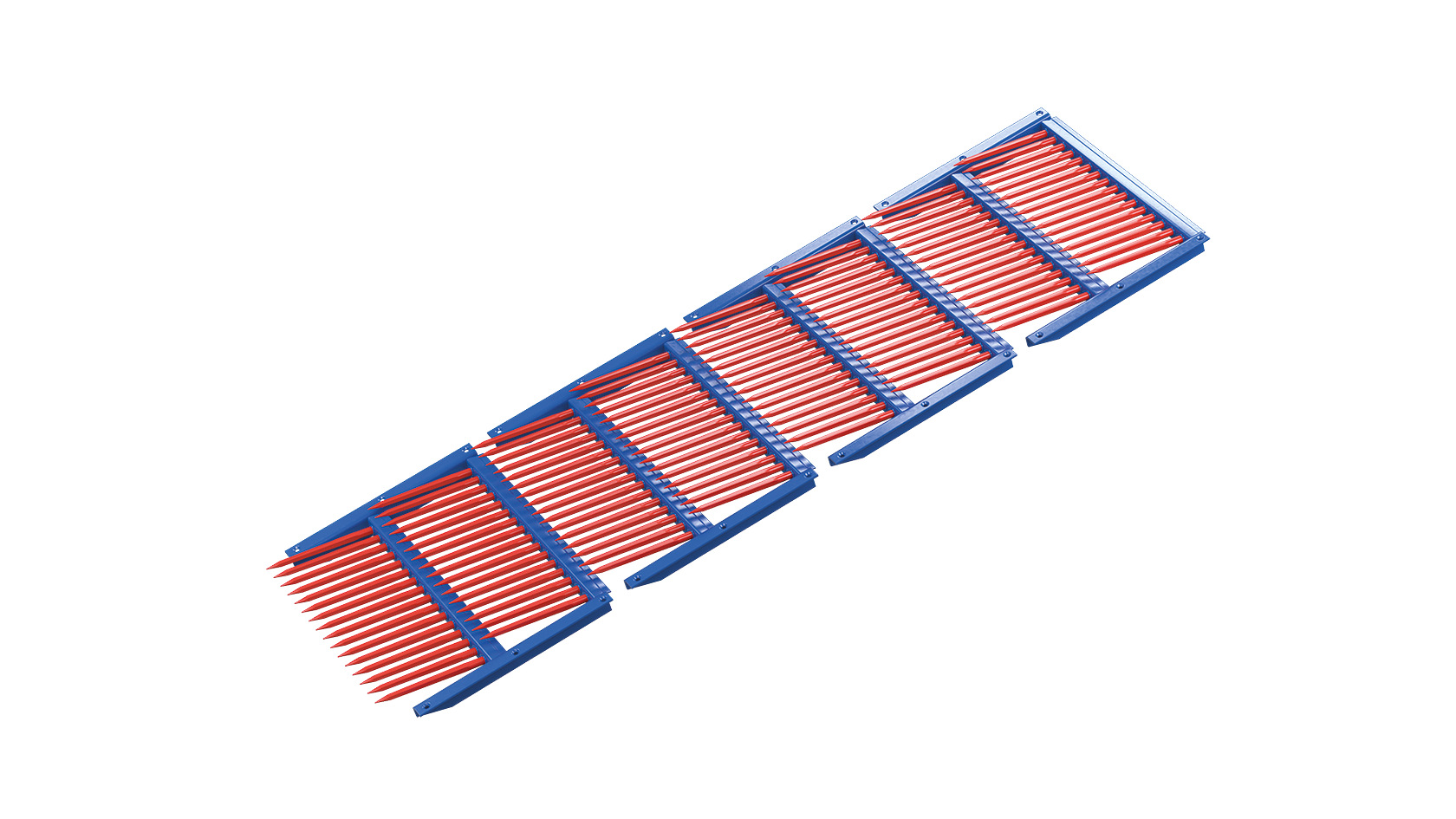

Hydraulic folding grates

Genuine hydraulic folding grates from KLEEMANN separate the material entering the machine from materials that are too coarse.

| 100 mm | Upper deck | left | 1 pc. |

| 100 mm | Upper deck | centre | 3 pc. |

| 4 pc. |

| 100 mm | Upper deck | right | 1 pc. |

| 1 pc. |

| 100 mm | Upper deck | left | 1 pc. |

| 100 mm | Upper deck | right | 1 pc. |

| 1 pc. |

| 100 mm | Upper deck | left | 1 pc. |

| 100 mm | Upper deck | centre | 3 pc. |

| 4 pc. |

| 100 mm | Upper deck | left | 1 pc. |

| 100 mm | Upper deck | 30 pc. | 33 pc. |

| 100 mm | Upper deck | right | 1 pc. |

| 1 pc. |

Perforated plates

In order to withstand the enormous impact and friction stresses and maximise service life, perforated plates are used made of particularly wear-resistant material.

| 20 mm | Hexagonal | 30 mm | Feeding/discharge |

| Upper deck | Feeding/discharge, upper deck | 1 pc. |

| 20 mm | Hexagonal | 35 mm | Feeding/discharge |

| Upper deck | Feeding/discharge, upper deck | 1 pc. |

| 20 mm | Hexagonal | 40 mm | Feeding/discharge |

| Upper deck | Feeding/discharge, upper deck | 1 pc. |

| 20 mm | Hexagonal | 45 mm | Feeding/discharge |

| Upper deck | Feeding/discharge, upper deck | 1 pc. |

| 20 mm | Hexagonal | 50 mm | Feeding/discharge |

| Upper deck | Feeding/discharge, upper deck | 1 pc. |

| 20 mm | Hexagonal | 60 mm | Feeding/discharge |

| Upper deck | Feeding/discharge, upper deck | 1 pc. |

| 20 mm | Hexagonal | 70 mm | Feeding/discharge |

| Upper deck | Feeding/discharge, upper deck | 1 pc. |

| 20 mm | Hexagonal | 80 mm | Feeding/discharge |

| Upper deck | Feeding/discharge, upper deck | 1 pc. |

| 20 mm | Hexagonal | 30 mm | Feeding/discharge |

| Upper deck | Feeding/discharge, upper deck | 1 pc. |

| 20 mm | Hexagonal | 35 mm | Feeding/discharge |

| Upper deck | Feeding/discharge, upper deck | 1 pc. |

Slotted grates

Genuine KLEEMANN slotted grates are used for sticky and extremely coarse material entering the machine that is difficult to screen.

| 32 mm | Upper deck |

| 50 mm | Upper deck |

| 60 mm | Upper deck |

| 90 mm | Upper deck |

| 40 mm | Upper deck |

| 50 mm | Upper deck |

| 60 mm | Upper deck |

| 40 mm | Upper deck |

| 50 mm | Upper deck |

| 60 mm | Upper deck |

Vibrating grates

With the help of genuine KLEEMANN vibrating grates, coarse materials can be screened out in advance and the plant can be fed with material of a defined grain size.

| 32 mm | Lower deck | 8 mm | 2 pc. |

| 55 mm | Lower deck | 10 mm | 2 pc. |

| 60 mm | Lower deck | 10 mm | 2 pc. |

| 70 mm | Lower deck | 10 mm | 2 pc. |

| 90 mm | Lower deck | 12 mm | 2 pc. |

| 100 mm | Upper deck | left | 1 pc. |

| 100 mm | Upper deck | right | 1 pc. |

| 100 mm | Upper deck | left | 1 pc. |

| 150 mm | Upper deck | left | 1 pc. |

| 150 mm | Upper deck | right | 1 pc. |

Wire mesh

Screen linings are put to a tough test in everyday use. In order to permanently and reliably ensure that material is screened to the desired final grain size, KLEEMANN uses screen linings made of special wear-resistant stainless steel spring wire or round wires.

| for prescreening units | Lower deck | 1 pc. |

| for prescreening units | 10 mm | Lower deck | 4 mm |

| 1 pc. |

| for prescreening units | 12 mm | Lower deck | 4 mm |

| 1 pc. |

| for prescreening units | 15 mm | Lower deck | 4 mm |

| 1 pc. |

| for prescreening units | 18 mm | Lower deck | 4 mm |

| 1 pc. |

| for prescreening units | 20 mm | Lower deck | 5 mm |

| 1 pc. |

| for prescreening units | 25 mm | Lower deck | 6 mm |

| 1 pc. |

| for prescreening units | 30 mm | Lower deck | 8 mm |

| 1 pc. |

| for prescreening units | 35 mm | Lower deck | 8 mm |

| 1 pc. |

| for prescreening units | 40 mm | Lower deck | 8 mm |

| 1 pc. |

Due to possible technical changes, always refer to the information in the instruction manual.