Settings

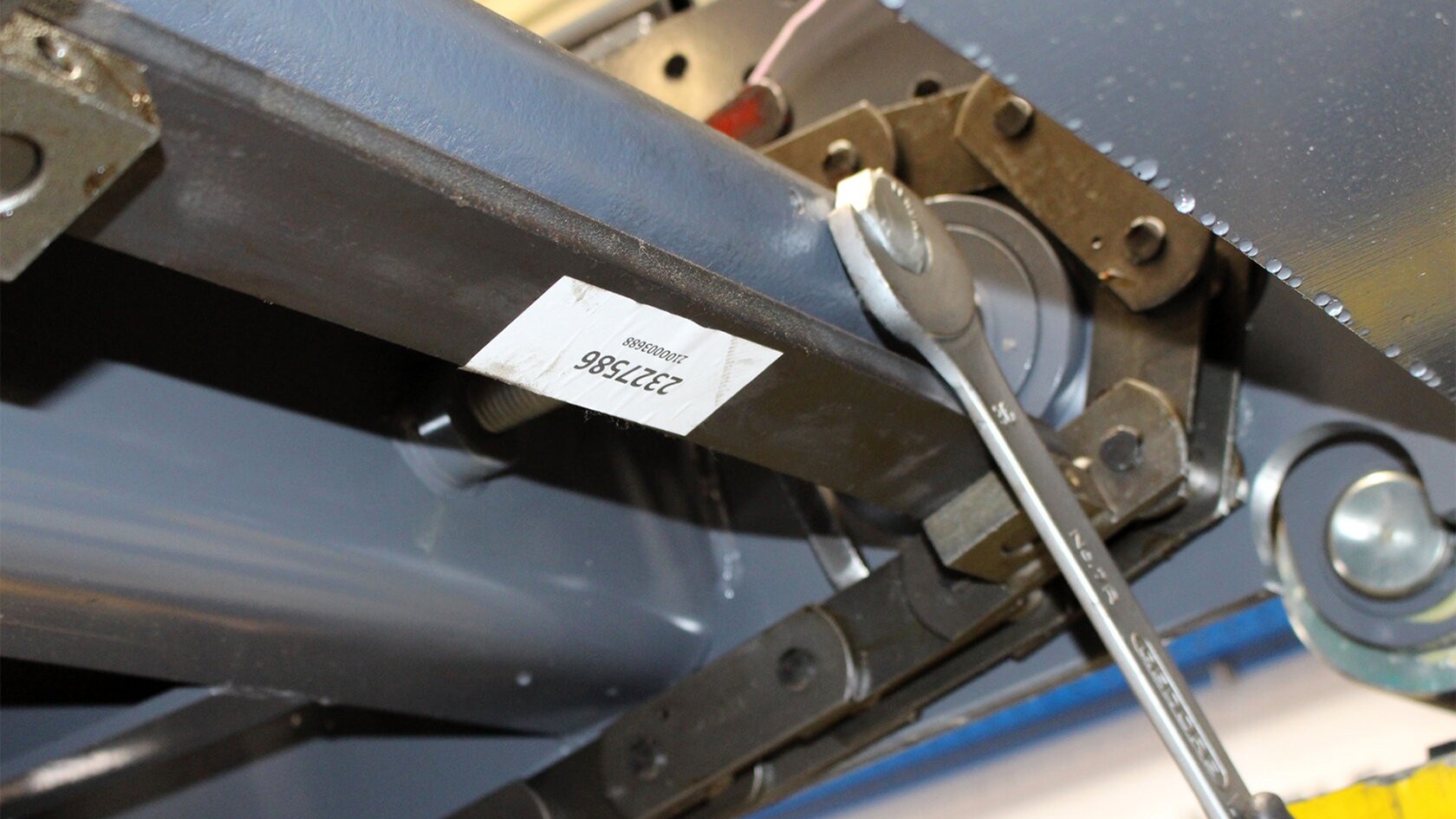

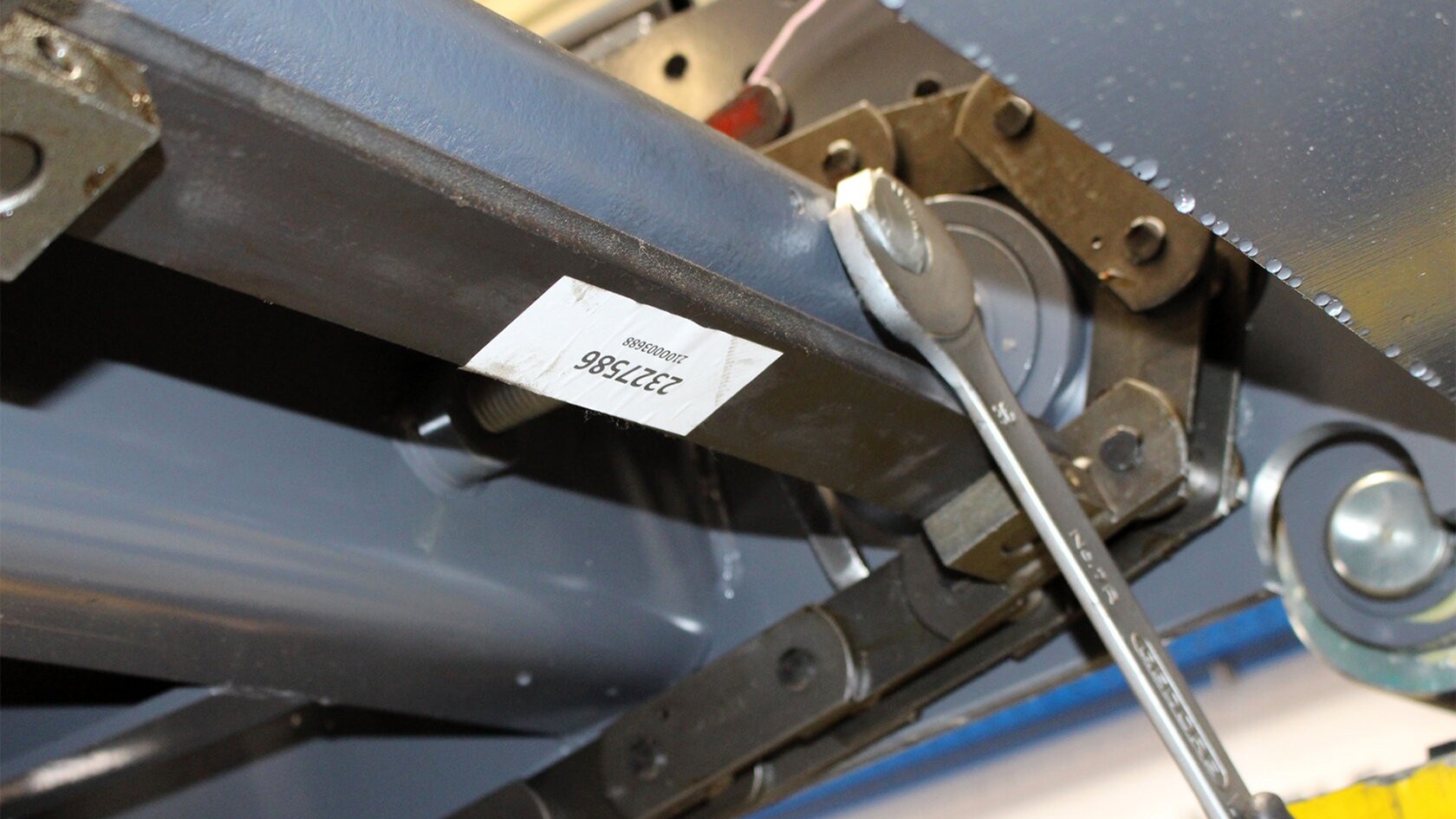

Regularly check whether the conveyor chain is correctly tensioned and adjust it if required. A correctly tensioned conveyor chain may not be under tension on its loose side at any time during movement. Excessively high tension of the conveyor chain causes irregular running or knocking.

The correct settings for all components are important for achieving operational readiness, minimising wear and preventing unnecessary downtimes.