The basics of lubricants

In general, lubricants are formulated from several components that can be split into two groups: the actual base oil and the supplementary additives that influence and give rise to the specifically desired properties of the lubricant.

Additives are oil-soluble supplements that are mixed into the base oils. Additives are always used when the properties of the base oil are insufficient for fulfilling the required purposes and in order to keep the finished product functional for as long as possible, even under the highest operational loads.

In the following, we will take a closer look at four important additives. Please note that numerous other additives are also used in oils.

ADDITIVES FOR REDUCED WEAR AND INCREASED CORROSION PROTECTION

Damage in combustion engines – such as pitting and, in extreme cases, engine seizure – often occurs when mechanical components such as camshafts and valves or hydraulic tappets come into contact with one another.To prevent such damage, special additives form thin, lubricant layers that effectively prevent undesirable friction between the components.

Substances such as water and oxygen, which are produced in the combustion process or are contained in fuel, significantly increase the risk of corrosion. This additive group forms dense, fur-like, and water-repellent barriers on metal surfaces that protect them against corrosion.

There are numerous other additives besides the ones mentioned here. We guarantee that you can purchase the oils with the additives you need for your WIRTGEN GROUP machines whenever you need them.

There is no such thing as a universal engine or gear oil. WIRTGEN GROUP machines require ideally formulated high-grade oils.

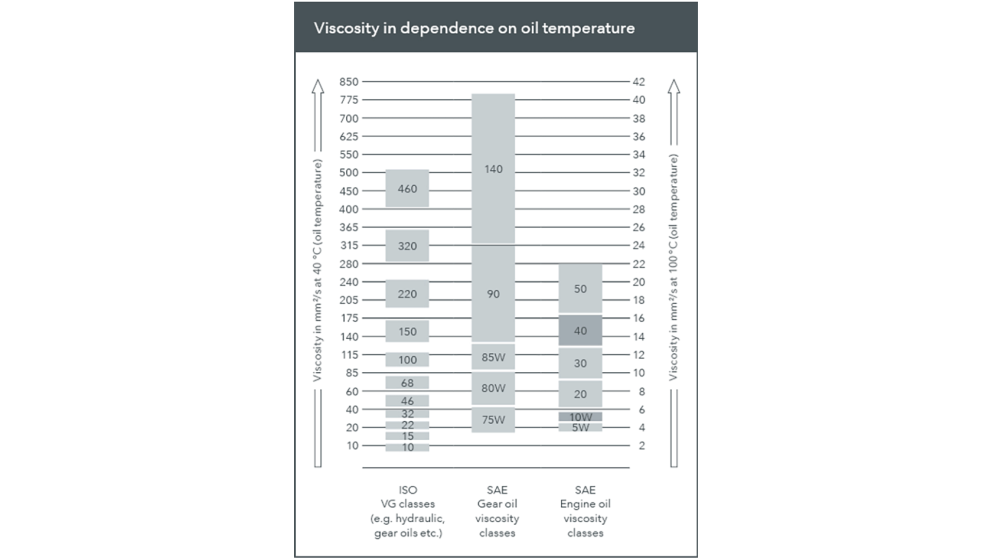

Within the context of lubricants, viscosity can be regarded as the property of a fluid to resist deformation (lubricant flow characteristic). The less fluid an oil is, the higher its viscosity. Viscosity is a temperature-dependent parameter: The viscosity of an oil becomes lower as its temperature rises during the working process.This change in viscosity varies from one oil to another. The range of variation is described with the aid of the viscosity index (VI). The higher the VI, the less the viscosity of the oil changes as its temperature increases. This index can be modified with the aid of VI improvers (additives).

The change in viscosity is directly dependent on the temperature. In this context, we speak of the VT behaviour (viscosity-temperature behaviour) of an oil. The change in viscosity in relation to the oil temperature is a logarithmic function: as the temperature of the oil falls, a disproportionate rise in its viscosity is observed.

High viscosity > less fluid > higher resistance

Low viscosity > more fluid > lower resistance

The graph compares the viscosity of engine and gear oils in centistoke (mm²/s) at the reference oil temperatures of 40°C and 100°C. In terms of their SAE specification (viscosity), engine and gear oils can have the same values, yet with respect to other values (additives, manufacturers' standards, etc.) they do not correspond with each other. At an oil temperature of 40°C, the 10W-40 engine oil (highlighted in the diagram) has a viscosity of approx. 180 mm²/s and, at 100°C, a value of approx. 4 mm²/s.

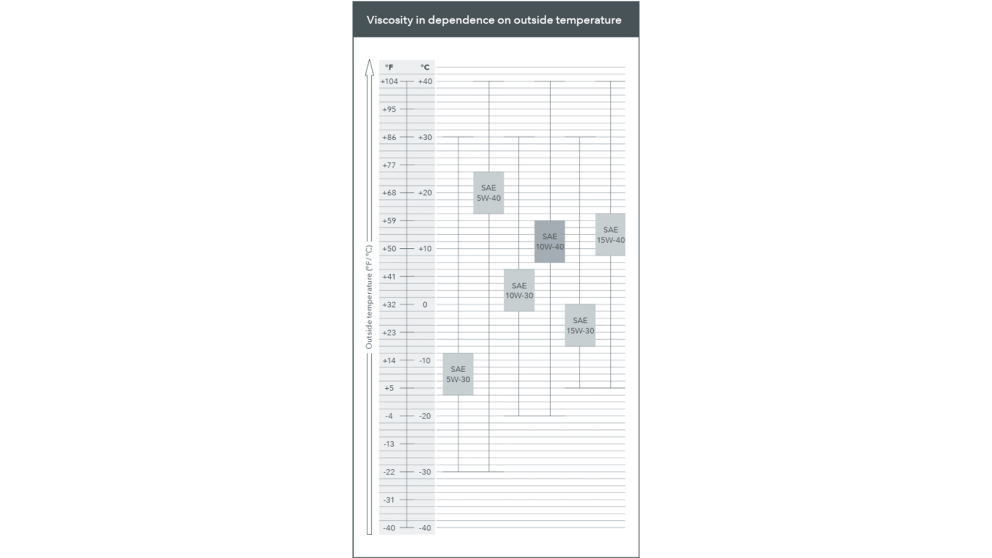

In everyday operations, it is preferable to maintain a viscosity that is as consistent as possible to ensure optimum lubrication over the entire temperature range. Engine oils with low viscosity margins facilitate trouble-free, year-round engine operation under all kinds of operating conditions: from cold starts in winter to working in regions with the hottest temperatures in summer.

SAE is the acronym for the Society of Automotive Engineers. This is an organisation that has defined a set of classifications for oils.

For many buyers, the SAE classification (for example, 10W-40) is the decisive quality criterion when choosing the right engine oil. It must be remembered, however, that SAE viscosity classes do not represent performance demands with respect to the engine or gearbox, but merely specify the viscosity at standard reference temperatures.

Please also compare the stipulations of the individual engine manufacturers laid out in the instruction manual for your machine.

The ambient temperature is the crucial factor when it comes to making the right choice. Short periods with temperatures below the temperature limit may adversely affect the cold starting ability. Exceeding the temperature limit for longer periods should also be avoided to minimise wear. The diagram shows a recommended temperature range of -20°C to +40°C for the use of an SAE 10W-40 engine oil (highlighted in the diagram).

Specifications help in selecting the right lubricating oil. In order to depict the additional lubricant requirements of different engines, there are, on the one hand, specifications that are valid for all manufacturers or classifications defined by national and international organisations.

On the other hand, there are also approved oils lists issued by engine manufacturerssuch as:

You can look up which oil is the right oil for your machine in the instruction manual.

Whether a lubricant is suitable for or can be used in a specific lubrication system is defined by the manufacturer's standard and/or the ACEA and API specification.

The API specification is the applicable standard for the American market. It is divided into three classifications:

API specifications are assigned when engine or gear lubricants have been subjected to the following four tests:

Continuous testing and introduction of oils with the latest specifications can progressively increase the service intervals of WIRTGEN GROUP machines. Maintenance costs are thereby reduced.

This is only possible when the engine oil demonstrates consistently robust performance throughout this period without any adverse effects on the positive properties of the oil, e.g. with respect to component lubrication.