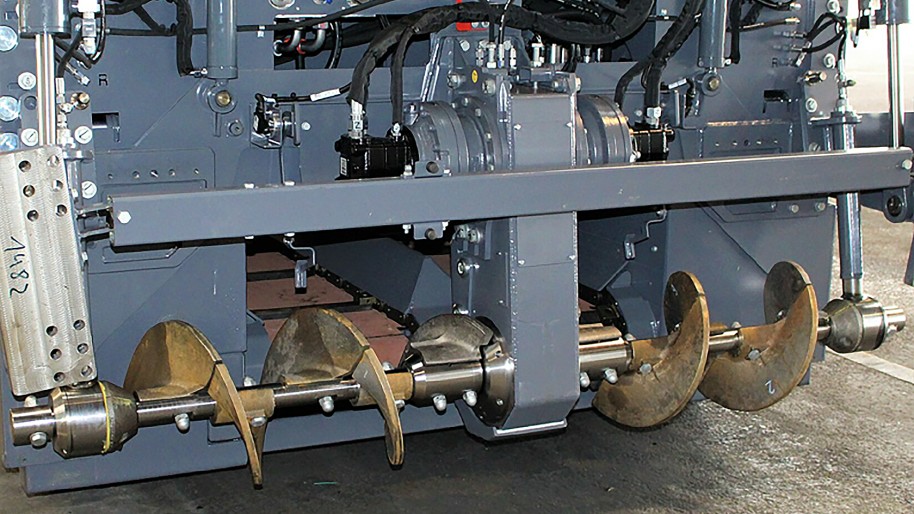

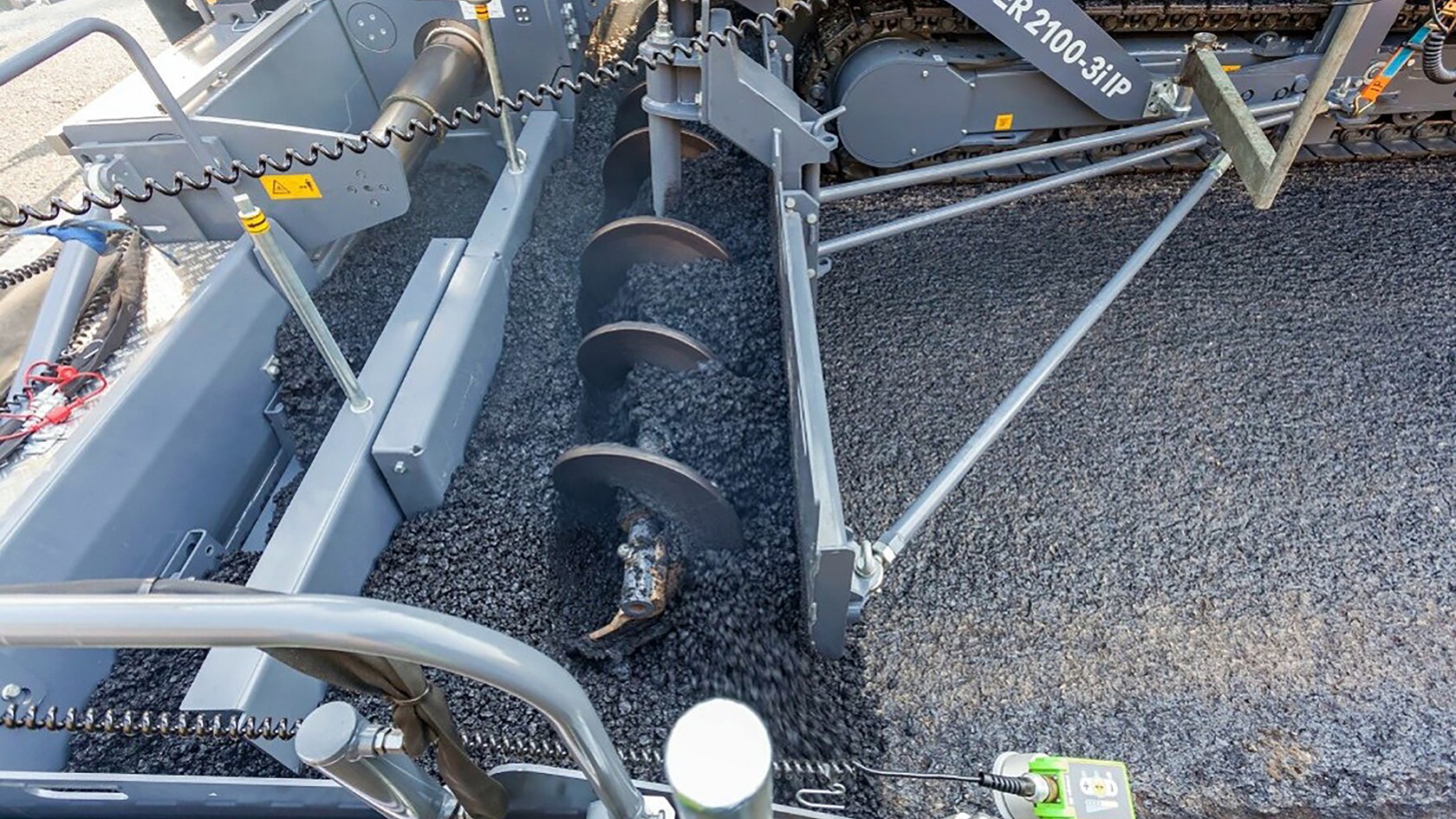

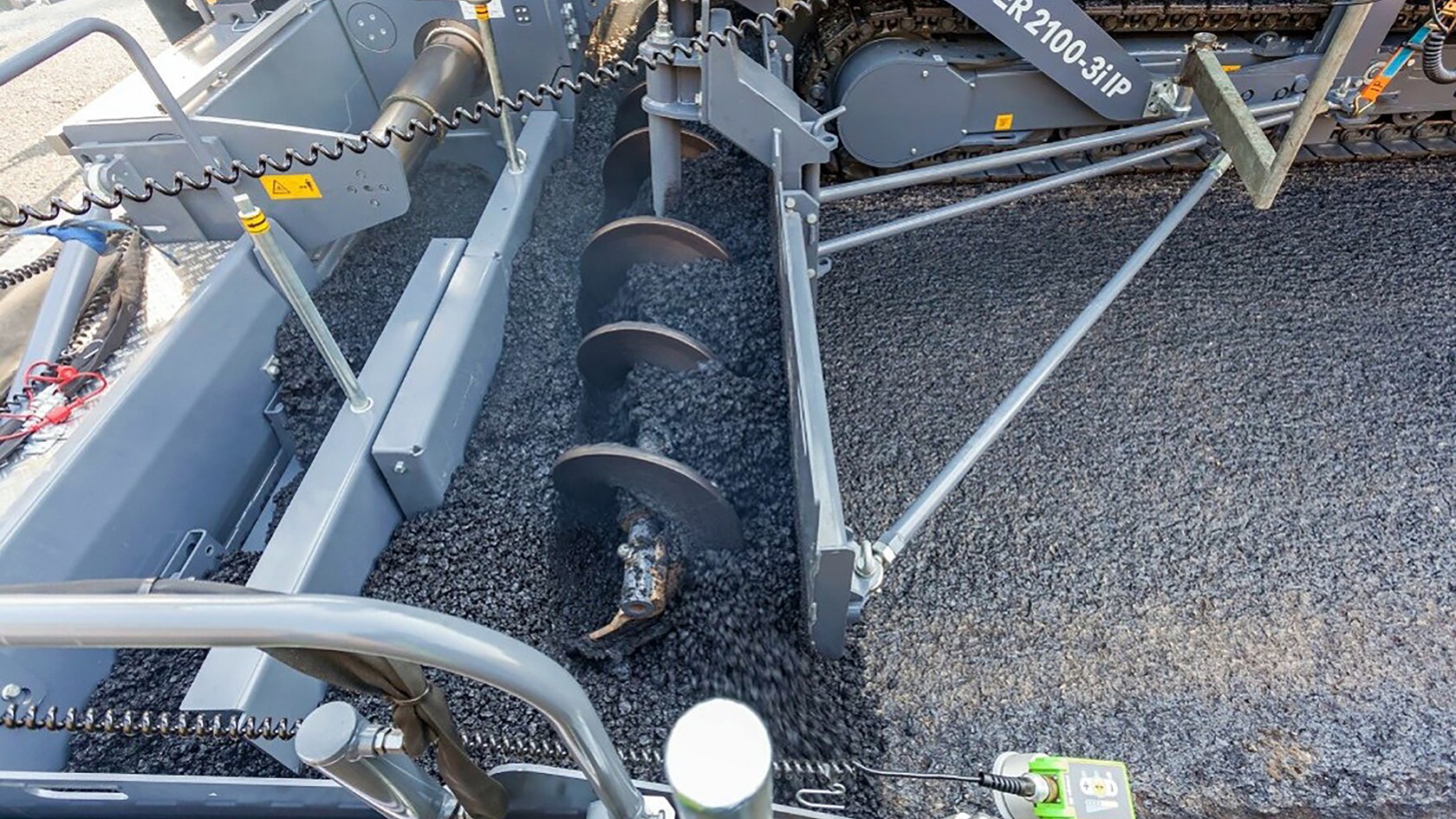

Spreading augers

The spreading auger spreads the material transported by the conveyor chains in front of the screed. The amount of material in front of the screed has a major influence on the equilibrium of forces on the screed, and, in return, on its floating behaviour.

On all VÖGELE SUPER series pavers, the hydraulic cylinder allows the entire centre auger bearing box to be raised or lowered by 15 cm to enable correct adjustment to the desired paving thickness.