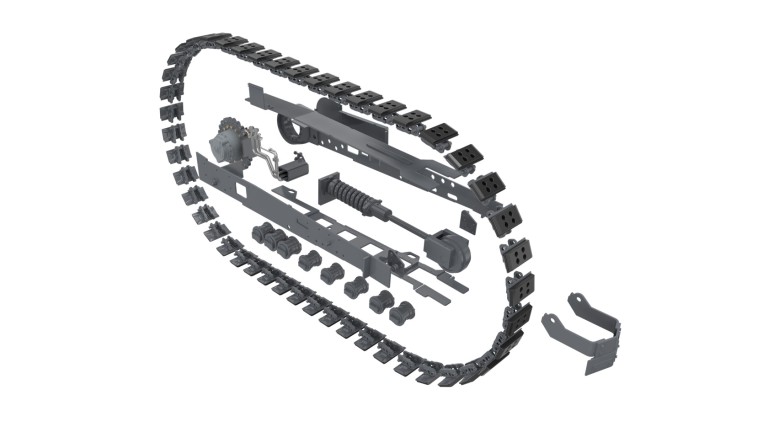

VÖGELE undercarriage components

Among the most frequent reasons for undesirable wear are:

Increasing service life means:

Leakage is the reason generally given to justify the premature replacement of track rollers.

However, a distinction must be made between leakage and untightness.

Due to the sliding bearing seal, the leakage of small amounts of oil is perfectly normal and, in industry jargon, is commonly referred to as ‘sweating’. This absolutely typical occurrence in the case of sliding bearing seals cleans the lapped surfaces of the sliding rings and prevents the ingress of dirt into the roller or sliding bearings in the track roller.

Track rollers with leaking or seized bearings should be replaced as soon as possible to avoid damage or wear to other track unit components, e.g. the track chain. This because the blocked rotation of track rollers can lead to rapid wear on the track chains, as it increases the frictional forces on the track roller casing and the contact surfaces of the chain links. At the same time, a pressure increase in the hydraulic system of the advance drive will be observed, since the necessary energy to propel the track unit increases. High loadings will also occur on other mechanical components, such as for example, on the tooth flanks of the drive gear or the bushes that protect the chain bolts.