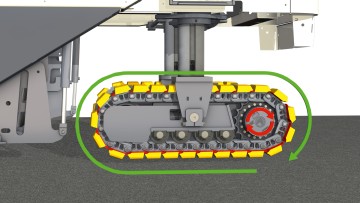

Drive sprockets

On all WIRTGEN tracked machines, the drive unit is friction-locked to the drive sprocket. This ensures that the engine power is efficiently and effectively transmitted to the track chains, where it is transformed into high-traction forward motion. The drive sprocket transmits the drive torque of the respective hydraulic motor to the link chain via a gearbox by engaging with the track chain, rotating and thus setting the crawler unit in motion.

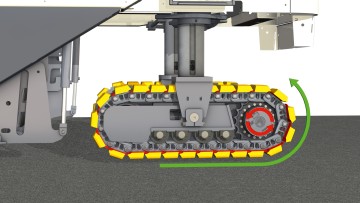

In crawler units, the drive sprockets are located on the rear axle in the direction of travel. When reversing, track wear is higher because the load on the track chain is increased by the longer tight span over the idler sprocket. Long periods of reverse travel therefore considerably accelerate wear on crawler unit components. During forward travel without milling, the shorter tight span reduces the load on the crawler unit parts. This means that crawler unit wear can be kept to a minimum by using forward travel when relocating the machine.