Crushing tools for impact crushers

Quickly and easily order and buy genuine crushing tools for KLEEMANN impact crushers online.

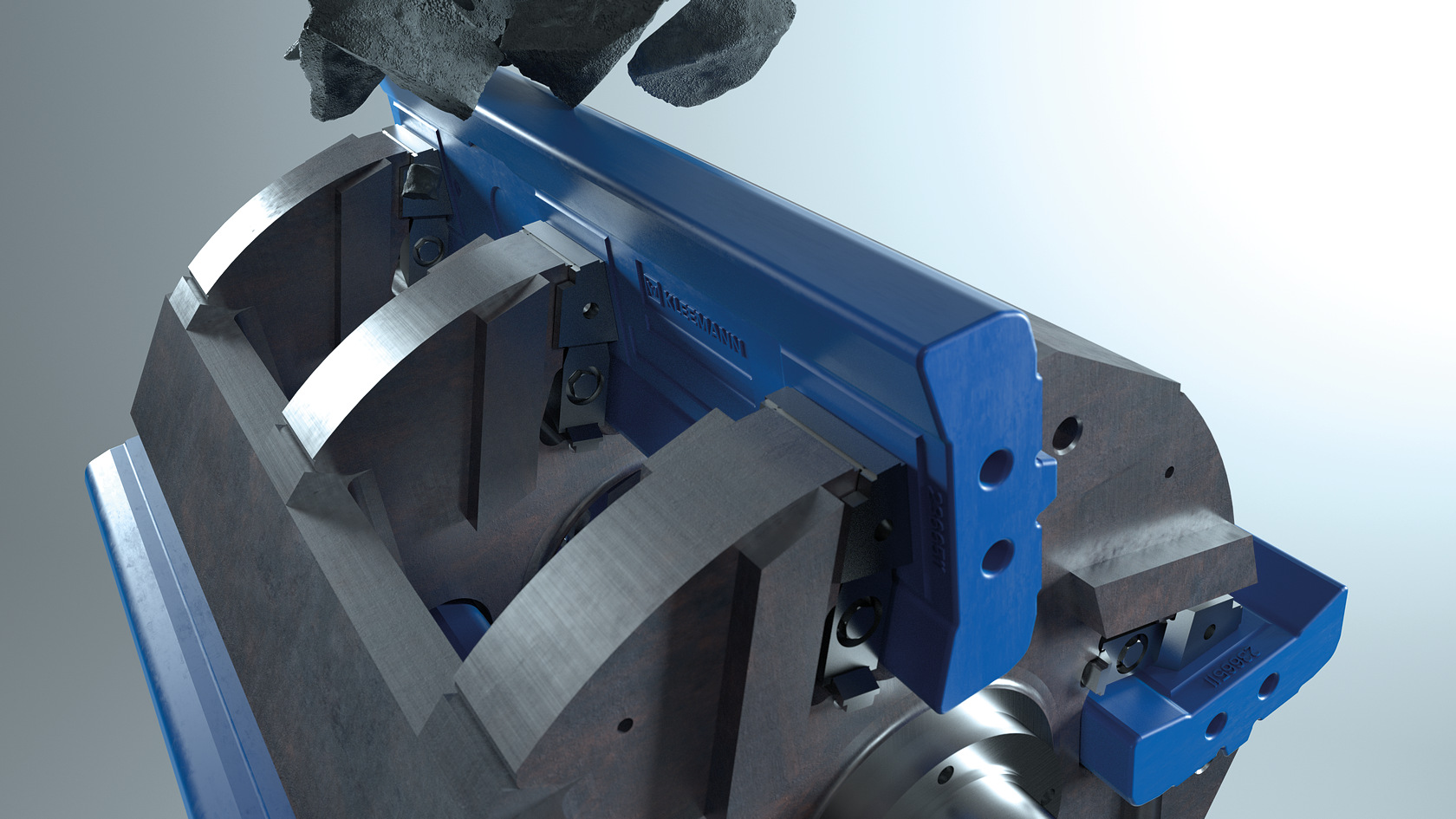

Blow bars

Achieving an outstanding crushing result with low wear costs is significantly influenced by the choice of the right blow bars. Genuine KLEEMANN blow bars offer more than just the right dimensions – the materials used, alloying elements and the entire casting process all play an important role in creating a reliable crushing tool.

| Martensitic ceramic (higher ceramic insert) | Building rubble, mixed; Reinforced concrete; Natural stone, medium-hard; Natural stone, hard; Asphalt; Gravel | Yes | for 4-piece rotor high/low |

| 2 pcs. | 0-350; 0-400; 0-500; 0-600; 0-700 |

| Martensitic ceramic (higher ceramic insert) | Building rubble, mixed; Reinforced concrete; Natural stone, medium-hard; Natural stone, hard; Asphalt; Gravel | Yes | for 4-piece rotor |

| 4 pcs. | 0-350; 0-400; 0-500; 0-600; 0-700 |

| Martensitic ceramic (higher ceramic insert) | Building rubble, mixed; Reinforced concrete; Natural stone, medium-hard; Natural stone, hard; Asphalt; Gravel | Yes | for 4-piece rotor |

| 4 pcs. | 0-350; 0-400; 0-500; 0-600; 0-700 |

| Chrome steel - ceramic | Building rubble, mixed; Natural stone, medium-hard; Natural stone, hard; Asphalt; Gravel | No | for 4-piece rotor high/low |

| 2 pcs. | 0-350 |

| Chrome steel - ceramic | Building rubble, mixed; Natural stone, medium-hard; Natural stone, hard; Asphalt; Gravel | No | for 4-piece rotor |

| 4 pcs. | 0-350 |

| Martensitic steel | Soft natural stone; Building rubble, mixed; Natural stone, medium-hard | Yes | for 4-piece rotor high/low |

| 2 pcs. | 0-350; 0-400; 0-500; 0-600; 0-700 |

| Martensitic steel | Soft natural stone; Building rubble, mixed | Yes | for 4-piece rotor |

| 4 pcs. | 0-350; 0-400; 0-500; 0-600; 0-700 |

| Martensitic ceramic (higher ceramic insert) | Building rubble, mixed; Reinforced concrete; Natural stone, medium-hard; Natural stone, hard; Asphalt; Gravel | Yes | for 4-piece rotor high/low |

| 2 pcs. | 0-350; 0-400; 0-500; 0-600; 0-700 |

| Martensitic ceramic (higher ceramic insert) | Building rubble, mixed; Reinforced concrete; Natural stone, medium-hard; Natural stone, hard; Asphalt; Gravel | Yes | for 4-piece rotor high/low |

| 4 pcs. | 0-350; 0-400; 0-500; 0-600; 0-700 |

| Manganese steel | Soft natural stone | Yes | for 4-piece rotor |

| 4 pcs. | 0-350; 0-400; 0-500; 0-600; 0-700 |

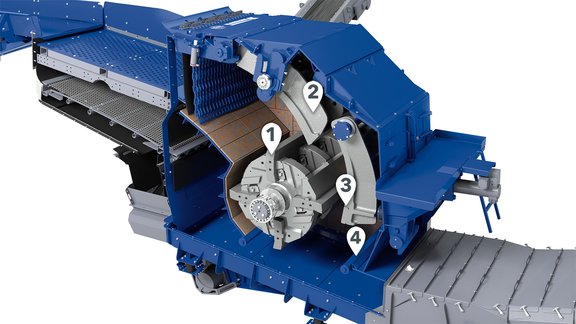

Impact bars

KLEEMANN only uses impact bars made of extremely wear-resistant material. The precise design of the plug connection ensures that it can be changed quickly during assembly.

| front |

| front |

| front; rear |

| front; rear |

| front; rear |

| front; rear |

| front; rear |

| front; rear |

Impact plates

Thick-walled impact plates made of KLEEMANN Resistant Steel protect the lower impact wings against premature wear.

| Manganese steel |

| Manganese steel |

| Manganese steel |

| Manganese steel |

| Martensitic steel with ceramic insert |

| Martensitic steel |

| Manganese steel |

| Martensitic steel with ceramic insert |

| Martensitic steel |

| Manganese steel |

Impact wings

To manufacture the impact wings, KLEEMANN only uses hard manganese steel with excellent work hardening for maximum wear resistance. The impact wings stand out for their long service life due to the thick-walled wear layer and optimum crushing results due to their special design.

| Monoblock design | upper |

| Monoblock design | lower |

| Monoblock design | lower |

| Monoblock design | upper |

| Monoblock design | lower |

| Monoblock design | upper |

| Monoblock design | lower |

| Monoblock design | upper |

| Monoblock design | lower |

| Monoblock design | upper |

Due to possible technical changes, always refer to the information in the instruction manual.